| Grounding Resistance Test | |

|---|---|

| Fall of Potential Test | |

|

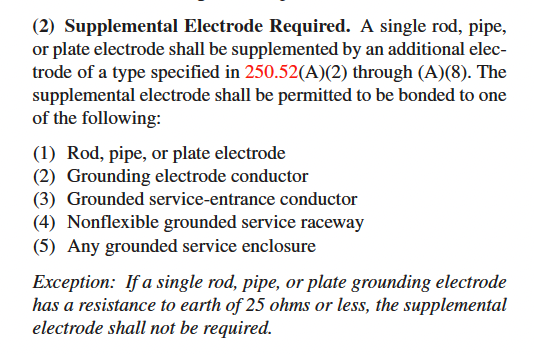

NEC Requirements and UL StandardsThe National Electric Code under Article 250.53 (A.2)

|

|

IEEE 142, “IEEE Recommended Practice for Grounding of Industrial and Commercial Power Systems”

IEEE 80

IEEE 81“Three Point Fall-of Potential”

IEEE 81.2

|

| Transformer Types | |

|---|---|

| Low Voltage, Greater than 600V | |

| Grounding |

|

| Soil Resistivity |

|

| 4-Point Test |

|

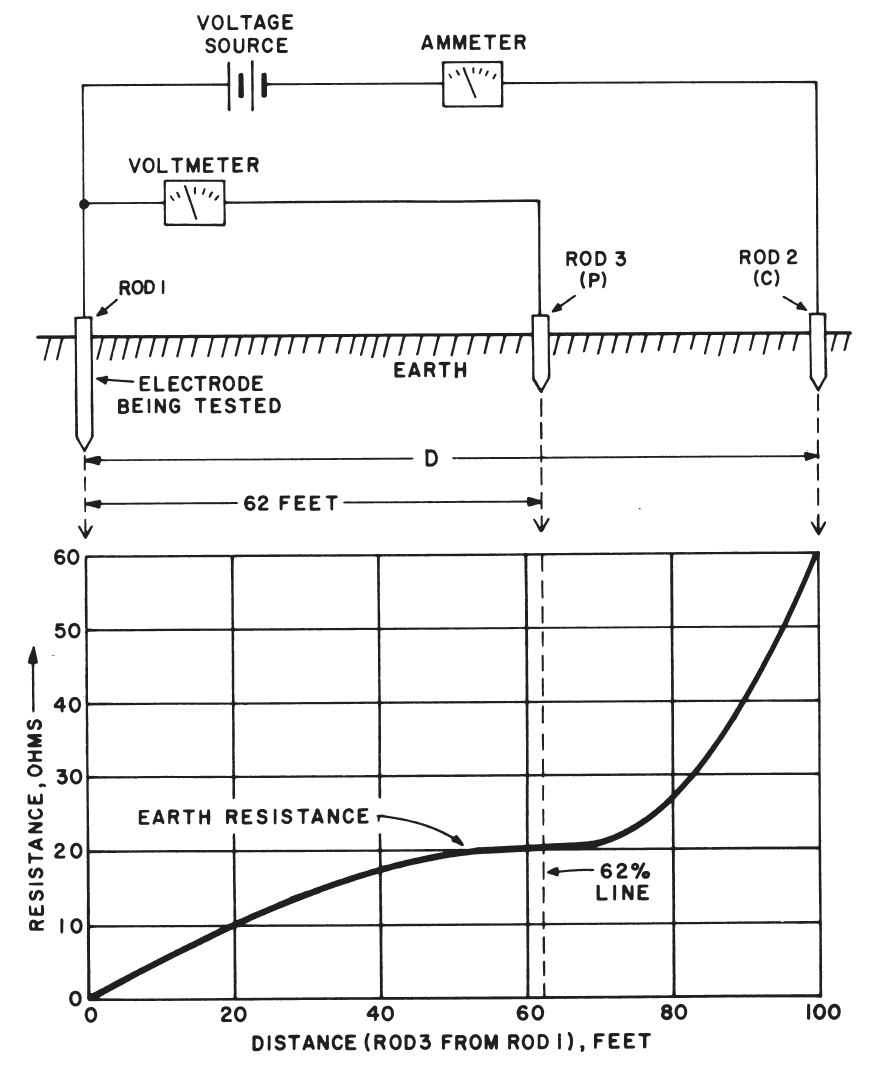

| Fall of Potential (3-point Method) | ||

|---|---|---|

| DESCRIPTION: |

This method measures grounding electrode resistance based upon the principle of potential drop across the resistance.

There are three basic types of the Fall-of-Potential test methods and a number of related test methods that will be described in the appendices.

The related test methods tend to be more complex and sophisticated requiring many measurements and/or a great deal of math. These methods have been developed to help overcome the problems faced when testing large ground systems or when there is limited space. A list of these methods follows:

|

|

| PROCEDURE: |

Test Item

Test Procedures

Figure 1(a)

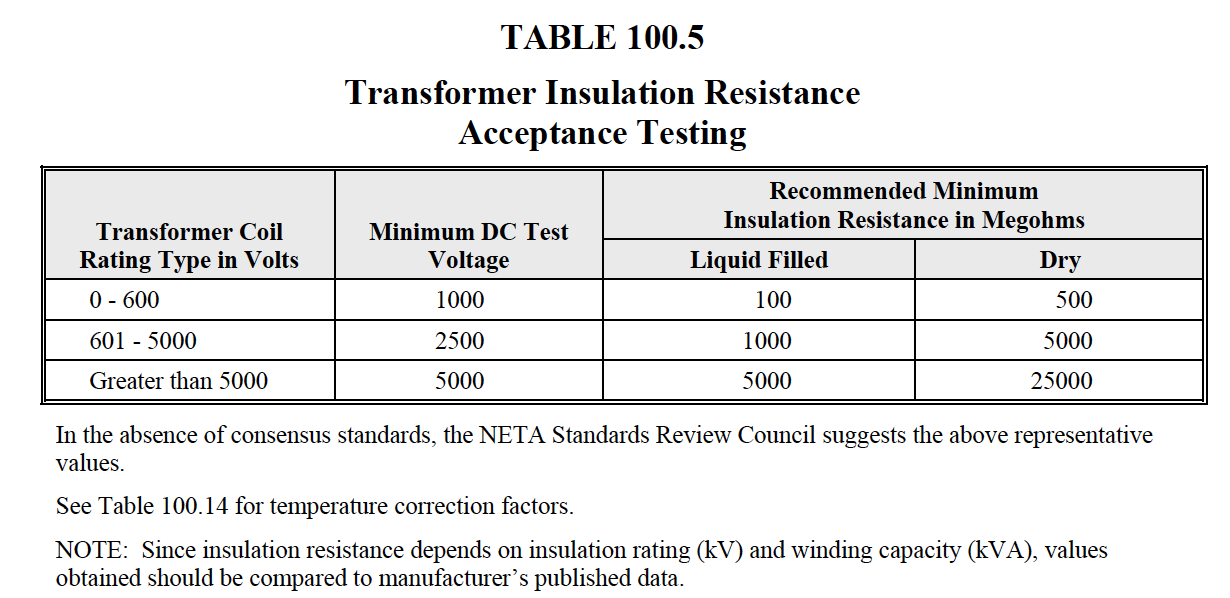

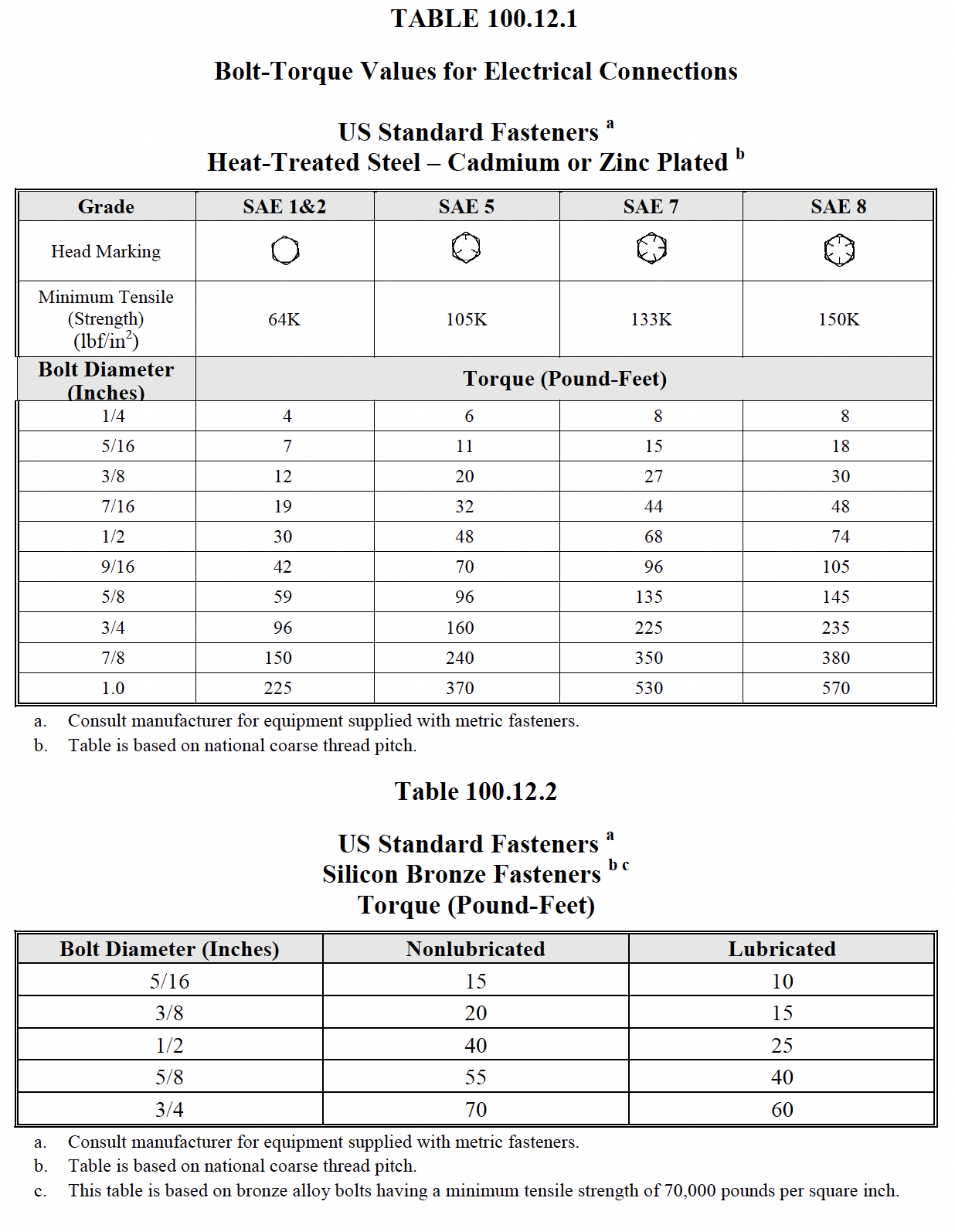

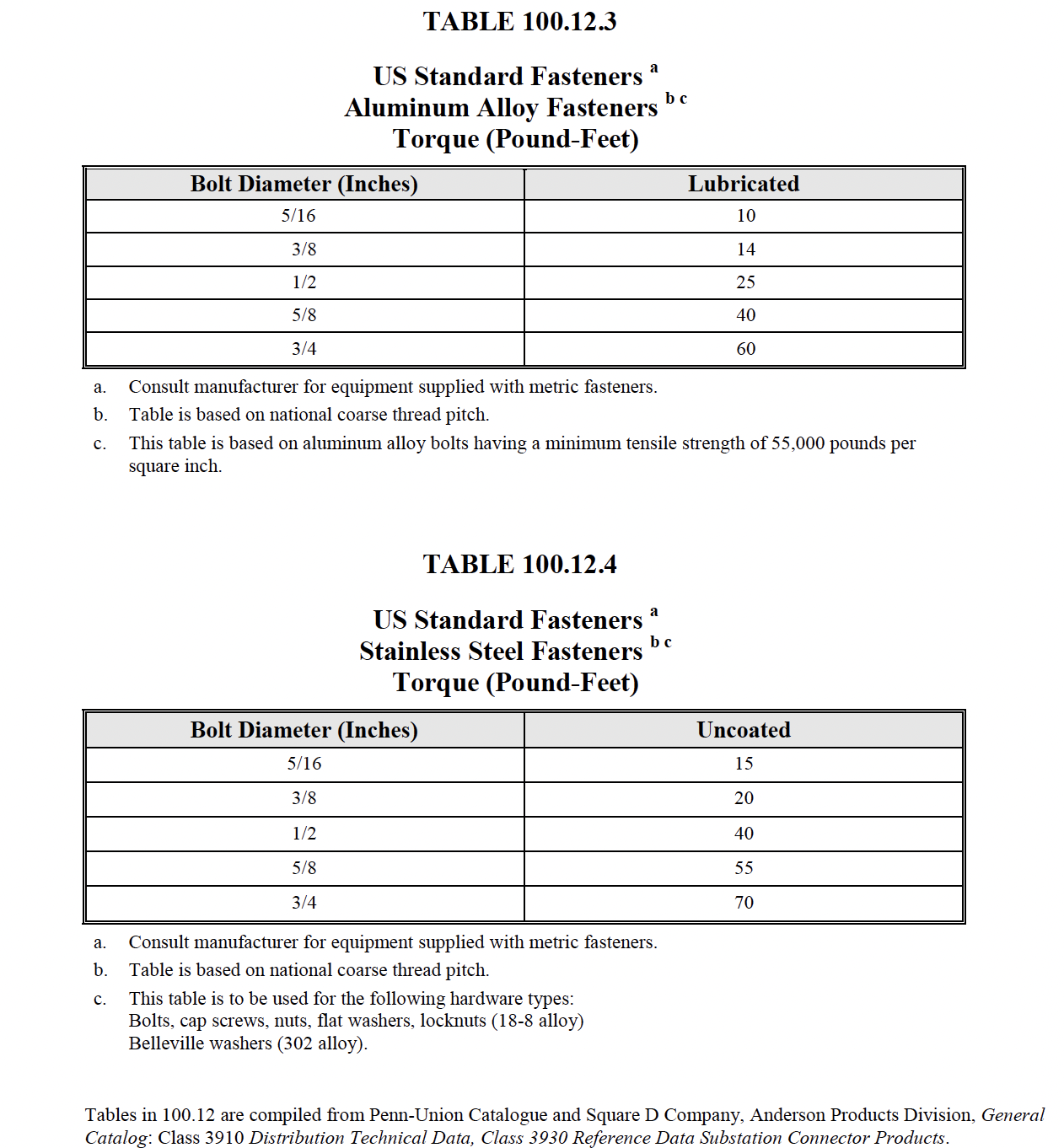

Figure 1(b)NETA MTS TABLE 100.5

Electrical Apparatus and Systems Other Than Rotating Machinery

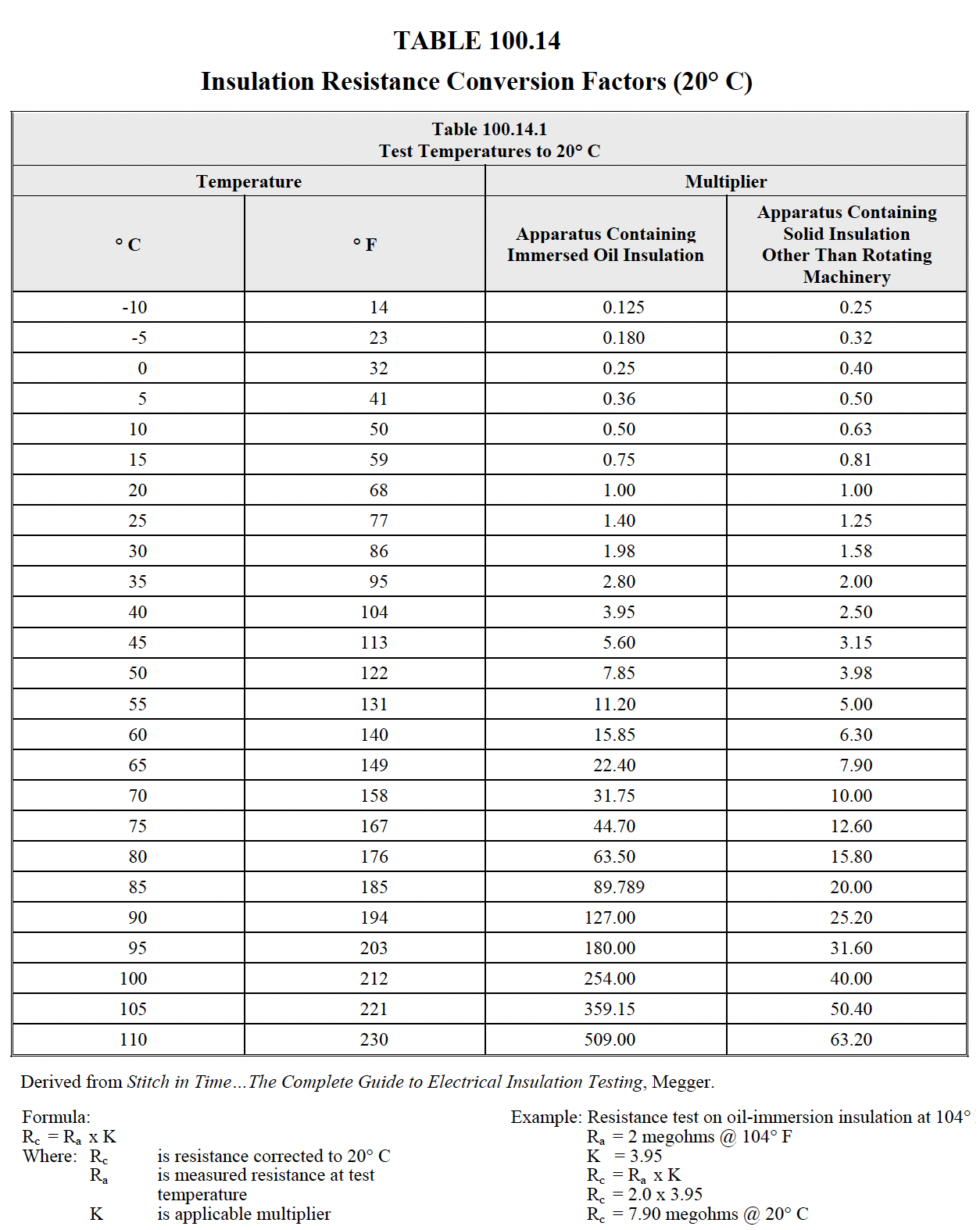

NETA ATS TABLE 100.14

|

|

| PURPOSE: |

Lorem ipsum dolor sit amet consectetur adipisicing elit. Cumque officiis, dolores aut saepe mollitia enim ipsum! Fuga, doloribus cumque eveniet blanditiis sapiente consequatur, accusamus inventore iusto sed tempora est sit? |

|

| NETA Test Procedure | |

|---|---|

NETA ATS7.13 Grounding SystemsA. Visual and Mechanical Inspection:

B. Electrical Tests:

C. Test Values – Visual and MechanicalC. Test Values – Visual and Mechanical

D. Test Values – Electrical

NETA MTS7.13 Grounding SystemsA. Visual and Mechanical Inspection:

B. Electrical Tests:

C. Test Values – Visual and MechanicalC. Test Values – Visual and Mechanical

D. Test Values – Electrical

NETA ATS / MTS

|

|