| Conductors | |

|---|---|

| Low Voltage, less than 600V | |

|

The National Electric Code 310.3 Conductors

The minimum size of conductors for voltage ratings up to and including 2000 volts shall be 14 AWG copper or 12 AWG aluminum or copper-clad aluminum, except as permitted elsewhere in this Code. Conductors in this article shall be of aluminum, copper-clad aluminum, or copper unless otherwise specified. Solid aluminum conductors 8, 10, and 12 AWG shall be made of an AA-8000 series electrical grade aluminum alloy conductor material. Stranded aluminum conductors 8 AWG through 1000 kcmil marked as Type RHH, RHW, XHHW, THW, THHW, THWN, THHN, service-entrance Type SE Style U, and SE Style R shall be made of an AA-8000 series electrical grade aluminum alloy conductor material. |

|

|

| Key Terms | |

|---|---|

| Insulation: |

Every electric wire is carefully covered with some form of electrical insulation. The wire itself is usually copper or aluminum, which is known to be a good conductor of the electric current that powers your equipment. The insulation must be just the opposite from a conductor: it should resist current and keep the current in its path along the conductor |

| Charging Current: |

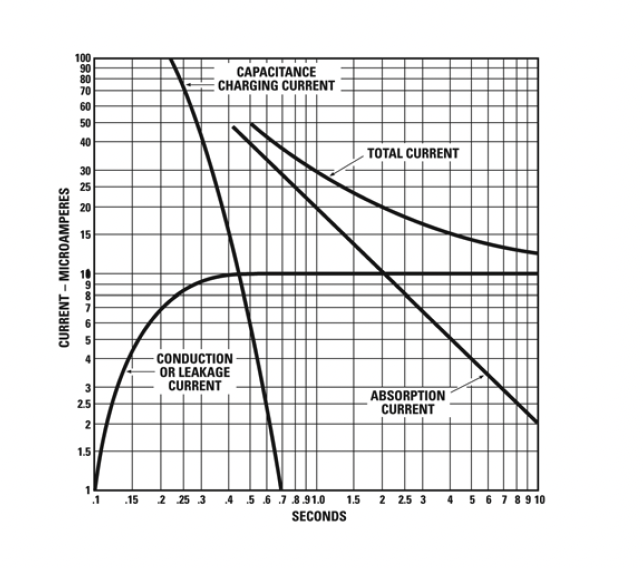

The measured Insulation resistance will be determined by the voltage applied and the resultant current (R = E/I). There are a number of things that affect current, including temperature of the insulation and humidity, as mentioned in the previous section. Right now, let’s just consider the nature of current through insulation and the effect of how long voltage is applied. Current through and along insulation is made up partly of a relatively steady current in leakage paths over the insulation surface. Electricity also flows through the volume of the insulation. Actually, as shown in Fig. 5, our total current comprises three components:

The total current is the sum of the three components and it is this current that can be measured directly by a microammeter, or in terms of megohms at a particular voltage by means of a Megger instrument (ohmmeter). Because the total current depends upon the time that the voltage is applied, you can see now why Ohm’s Law R = E/I only holds, theoretically, at an infinite time (that is, you’d have to wait forever before taking a reading). |

| Test Temperature |

The resistance of insulating materials decreases markedly with an increase in temperature. reliable comparisons between readings, you should correct the readings to a base temperature, such as 20℃, or take all your readings at approximately the same temperature For every 10℃ increase in temperature, halve the resistance; or, for every 10℃ decrease, double the resistance. |

| Dielectric Absorption Ratio |

The resistance of insulating materials decreases markedly with an increase in temperature. The ratio of two time-resistance readings (such as a 60-second reading divided by a 30-second reading) is called a dielectric absorption ratio. It is useful in recording information about insulation. If the ratio is a 10-minute reading divided by a 1-minute reading, the value is called the polarization index. |

| NETA Test Procedure | |

|---|---|

NETA ATS7.3.2 Cable Low-Voltage, 600-Volt MaximumA. Visual and Mechanical Inspection:

B. Electrical Tests:

C. Test Values – Visual and Mechanical

D. Test Values – Electrical

NETA MTS7.3.2 Cable Low-Voltage, 600-Volt MaximumA. Visual and Mechanical Inspection:

B. Electrical Tests:

C. Test Values – Visual and Mechanical

D. Test Values – Electrical

NETA ATS / MTS

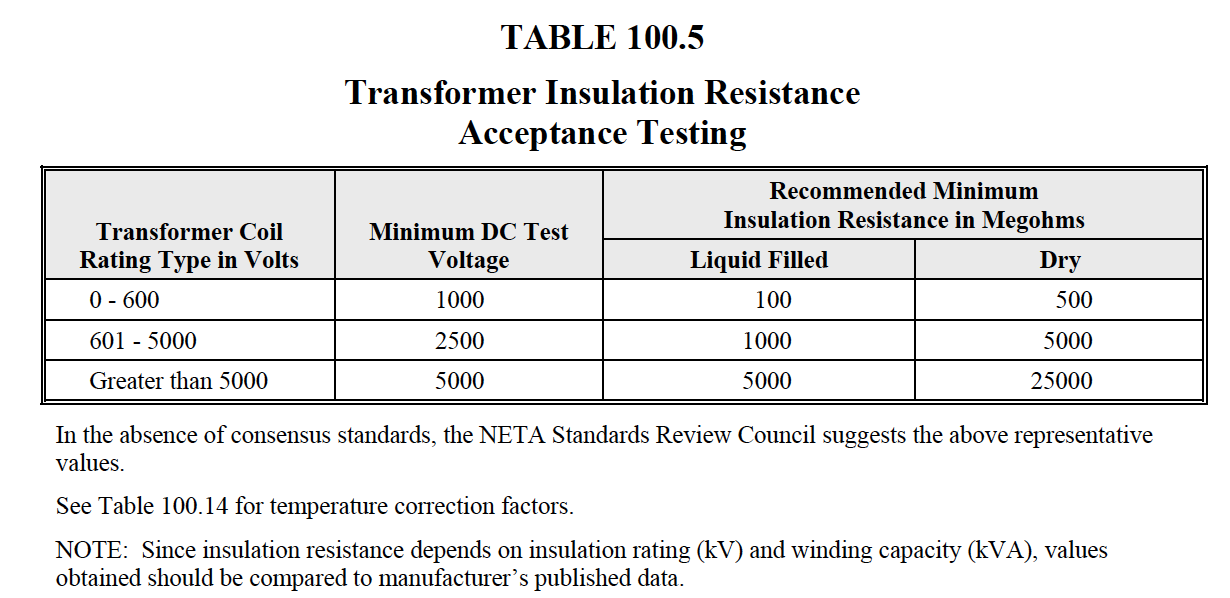

TABLE 100.5

NETA ATS / MTS

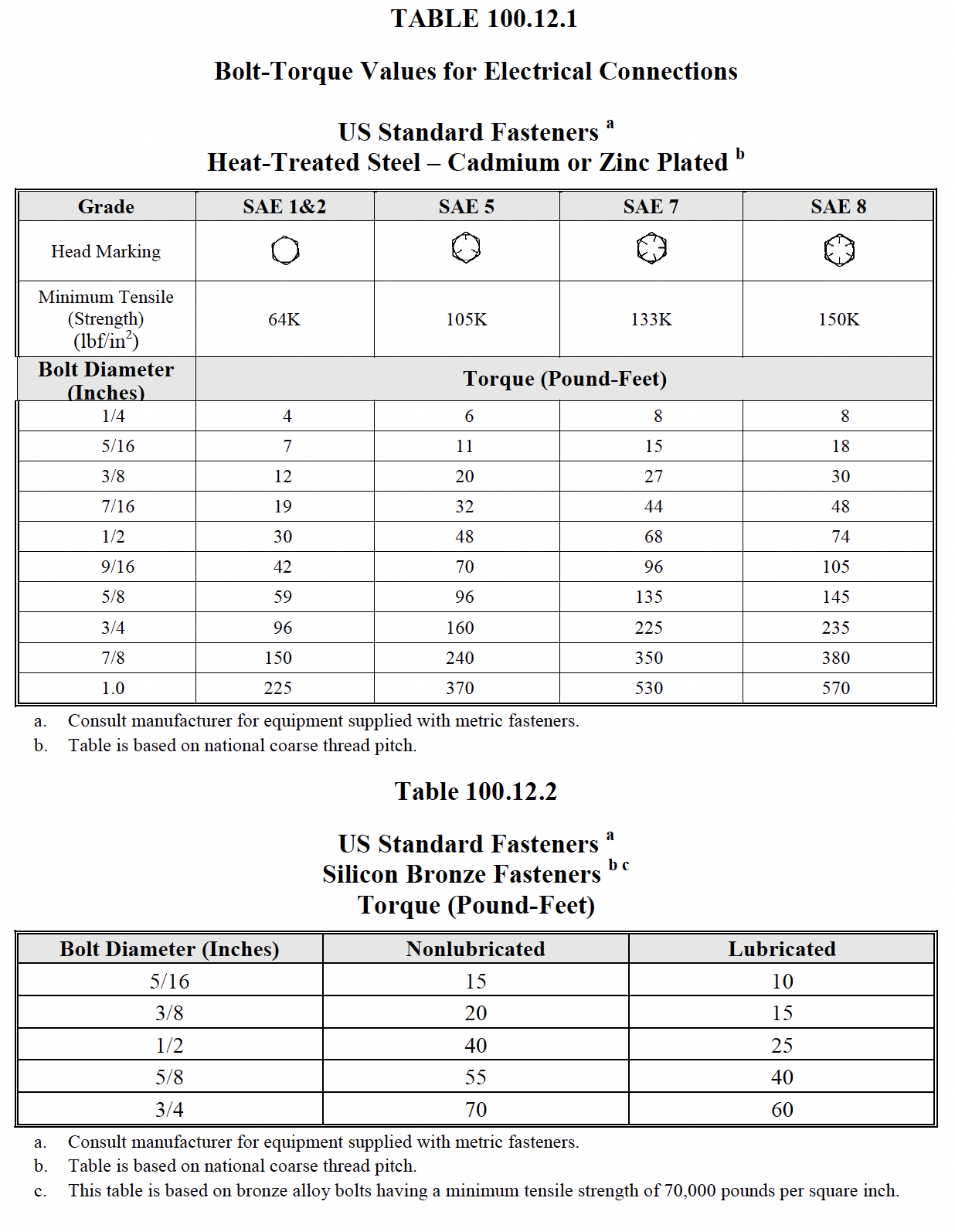

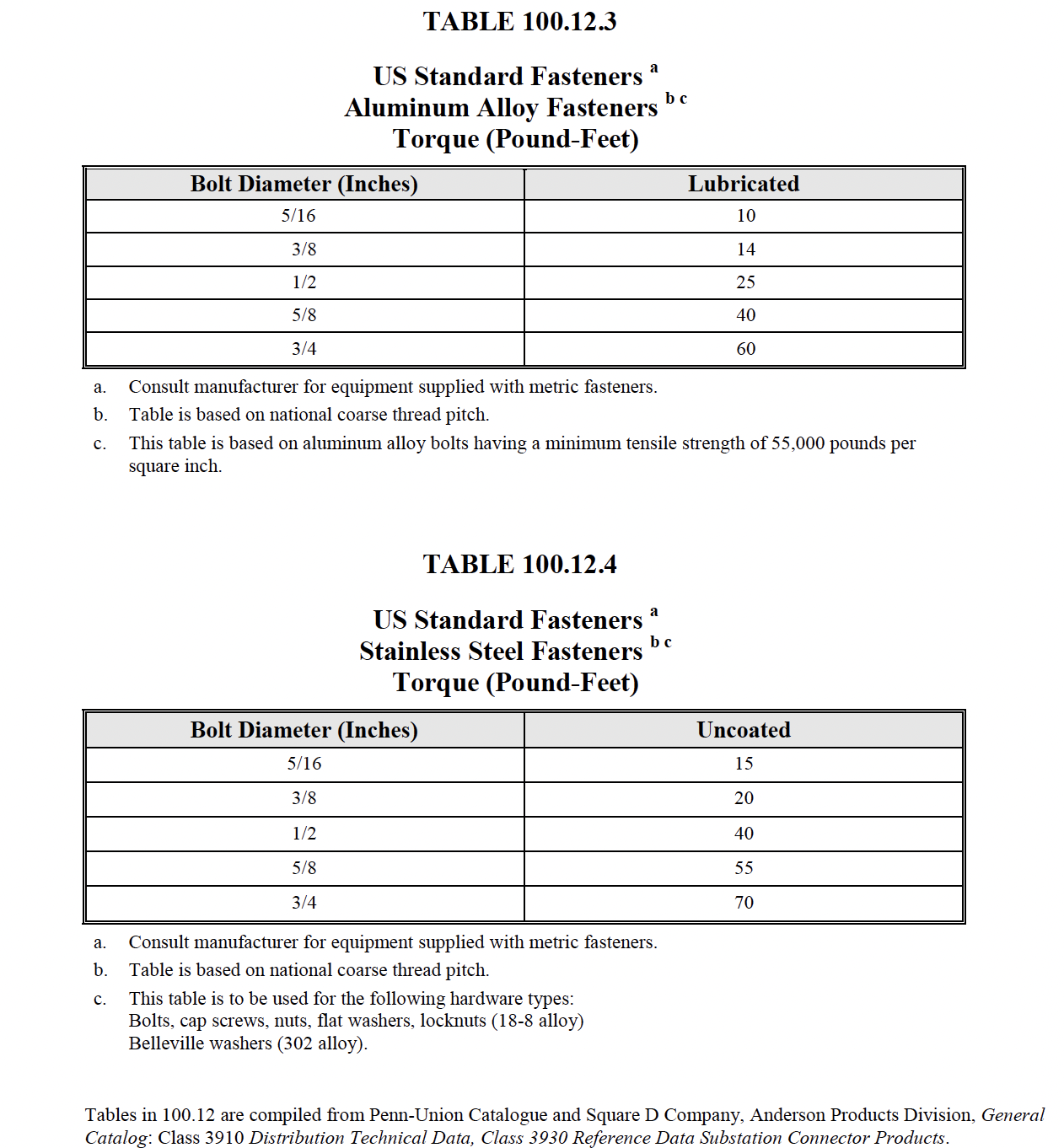

TABLE 100.12

|

|