NETA ATS

7.4 Metal-Enclosed Busways

A.

Visual and Mechanical Inspection:

- Compare equipment nameplate data with drawings and specifications.

- Inspect physical and mechanical condition.

- Inspect anchorage, alignment, and grounding.

- Verify correct connection in accordance with single-line diagram.

- Inspect bolted electrical connections for high resistance using one or more of the following

methods:

- Use of a low-resistance ohmmeter in accordance with Section 7.1.B.1.

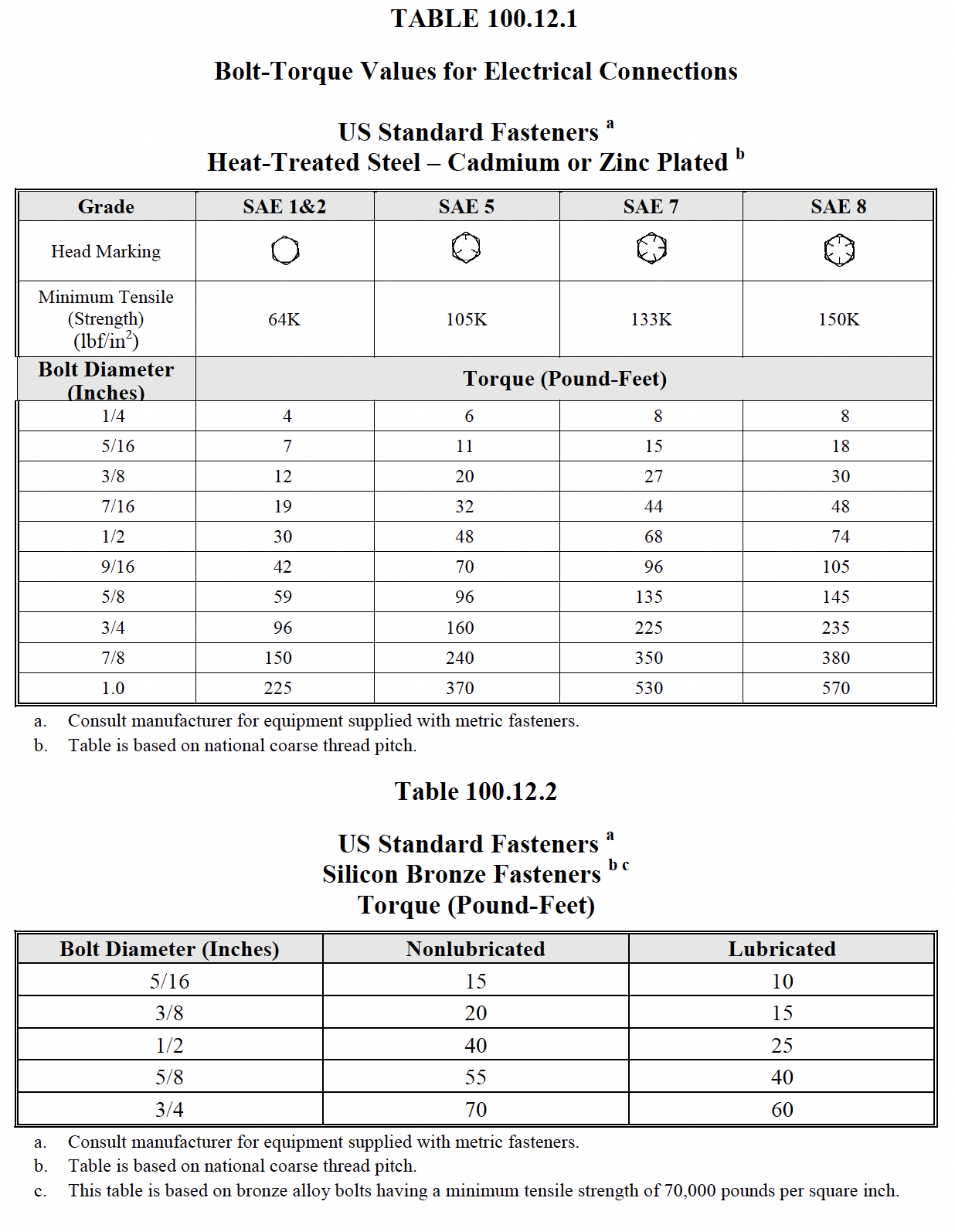

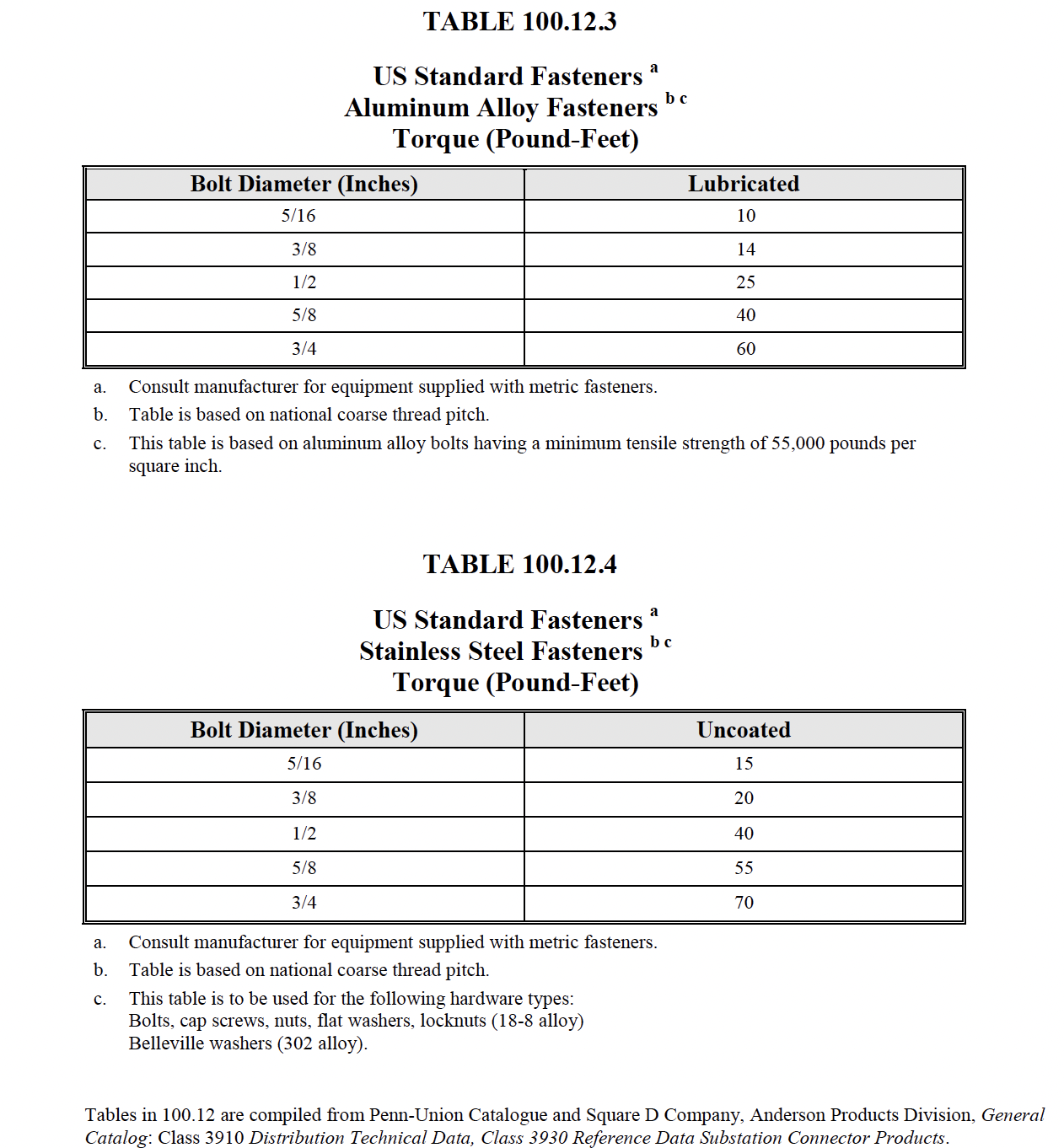

- Verify tightness of accessible bolted electrical connections by calibrated torquewrench

method in accordance with manufacturer’s published data or Table 100.12.

- Perform thermographic survey in accordance with Section 9.

- Confirm physical orientation in accordance with manufacturer’s labels to insure adequate

cooling.

- Examine outdoor busway for removal of “weep-hole” plugs, if applicable, and the correct

installation of joint shield.

B.

Electrical Tests:

- Perform resistance measurements through bolted connections and bus joints with a lowresistance

ohmmeter, if applicable, in accordance with Section 7.4.A.

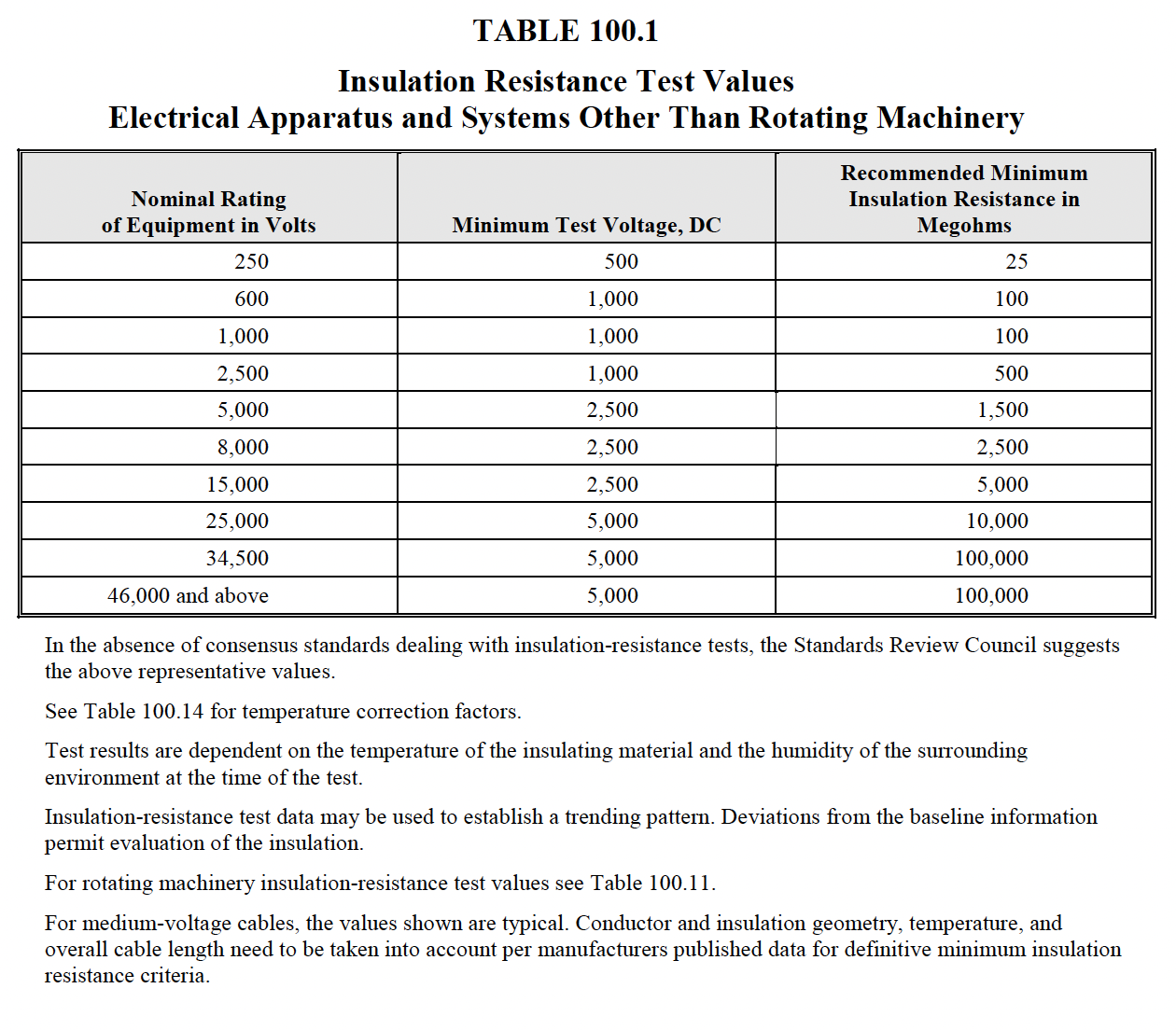

- Measure insulation resistance of each busway, phase-to-phase and phase-to-ground for one

minute, in accordance with Table 100.1.

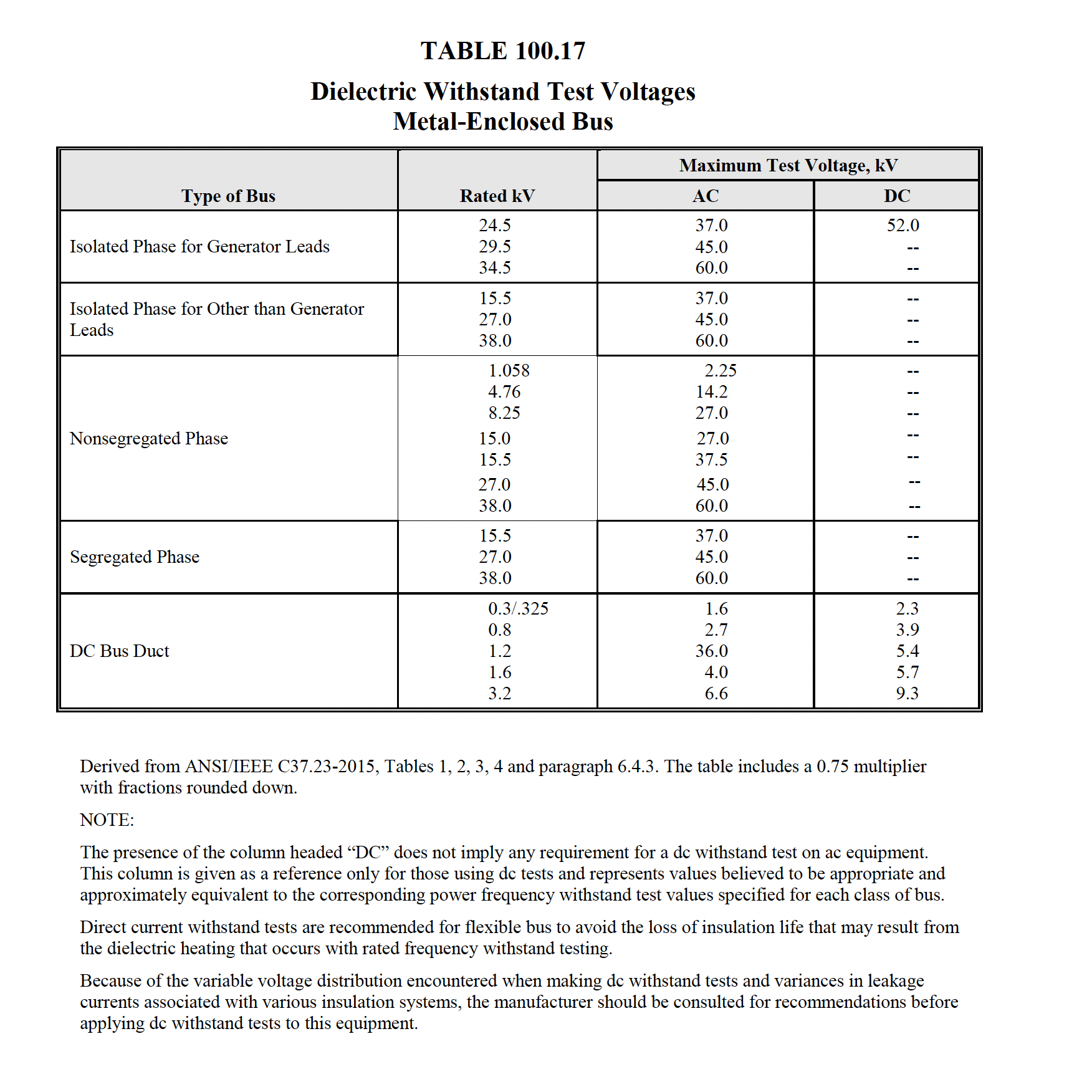

- Perform a dielectric withstand voltage test on each busway, phase-to-ground with phases not

under test grounded, in accordance with manufacturer’s published data. In the absence of

manufacturer’s published data, use Table 100.17. Where no dc test value is shown in Table

100.17, an ac value shall be used. The test voltage shall be applied for one minute.

- Measure resistance of assembled busway sections on insulated busway and compare values

with adjacent phases.

- Perform phasing test on each busway tie section energized by separate sources. Tests must

be performed from their permanent sources.

- Verify operation of busway space heaters.

C.

Test Values – Visual and Mechanical

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value. (7.4.A.5.1)

- Bolt-torque levels should be in accordance with manufacturer’s published data. In the

absence of manufacturer’s published data, use Table 100.12. (7.4.A.5.2)

- Results of the thermographic survey shall be in accordance with Section 9. (7.4.A.5.3)

D.

Test Values – Electrical

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value.

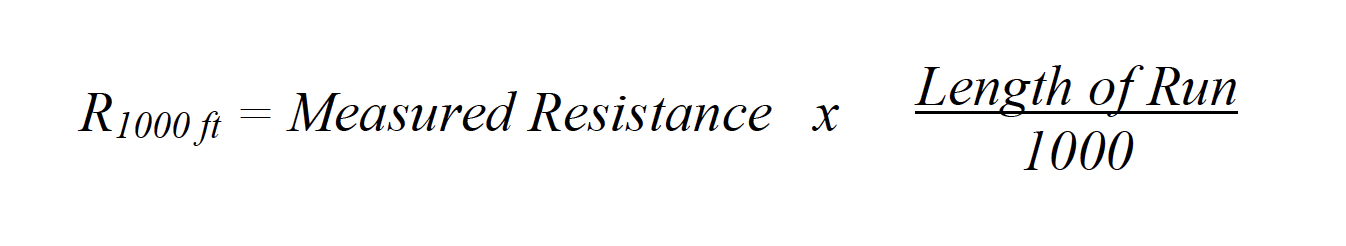

- Insulation-resistance test voltages and resistance values shall be in accordance with

manufacturer’s published data or Table 100.1. In the absence of manufacturer’s published

data, minimum resistance values are for a nominal 1000-foot busway run. Use the following

formula to convert the measured resistance value to the 1000-foot nominal value:

Converted values of insulation resistance less than those in Table 100.1 or manufacturer’s

minimum should be investigated. Dielectric withstand voltage tests shall not proceed until

insulation-resistance levels are raised above minimum values.

- If no evidence of distress or insulation failure is observed by the end of the total time of

voltage application during the dielectric withstand test, the test specimen is considered to

have passed the test.

- Microhm or dc millivolt drop values shall not exceed the high levels of the normal range as

indicated in the manufacturer’s published data. If manufacturer’s published data is not

available, investigate values which deviate from those of similar bus connections and

sections by more than 50 percent of the lowest value.

- Phasing test results shall indicate the phase relationships are in accordance with system

design.

- Heaters shall be operational.

NETA MTS

7.4 Metal-Enclosed Busways

A.

Visual and Mechanical Inspection:

- Inspect physical and mechanical condition.

- Inspect anchorage, alignment, and grounding.

- Inspect bolted electrical connections for high resistance using one or more of the following

methods:

- Use of a low-resistance ohmmeter in accordance with Section 7.1.B.1.

- Verify tightness of accessible bolted electrical connections by calibrated torquewrench

method in accordance with manufacturer’s published data or Table 100.12.

- Perform thermographic survey in accordance with Section 9.

- Confirm physical orientation in accordance with manufacturer’s labels to ensure adequate

cooling.

- Examine outdoor busway for removal of “weep-hole” plugs and for the correct installation

of joint shield.

- Inspect and clean ventilating openings.

B.

Electrical Tests:

- Perform resistance measurements through bolted connections and bus joints with a lowresistance

ohmmeter in accordance with Section 7.4.A.3.1.

- Perform insulation resistance tests on each busway for one minute, phase-to-phase and

phase-to-ground. Apply voltage in accordance with manufacturer’s published data. In the

absence of manufacturer’s published data, use Table 100.1.

- Perform a dielectric withstand voltage test on each busway, phase-to-ground with phases

not under test grounded, in accordance with manufacturer’s published data. If manufacturer

has no recommendation for this test, it shall be in accordance with Table 100.17. Where no

dc test value is shown in Table 100.17, ac value shall be used. The test voltage shall be

applied for one minute.

- *Perform a dielectric withstand voltage test on each busway, phase-to-ground with phases

not under test grounded, in accordance with manufacturer’s published data. If manufacturer

has no recommendation for this test, it shall be in accordance with Table 100.17. Where no

dc test value is shown in Table 100.17, ac value shall be used. The test voltage shall be

applied for one minute.

- Verify operation of busway space heaters.

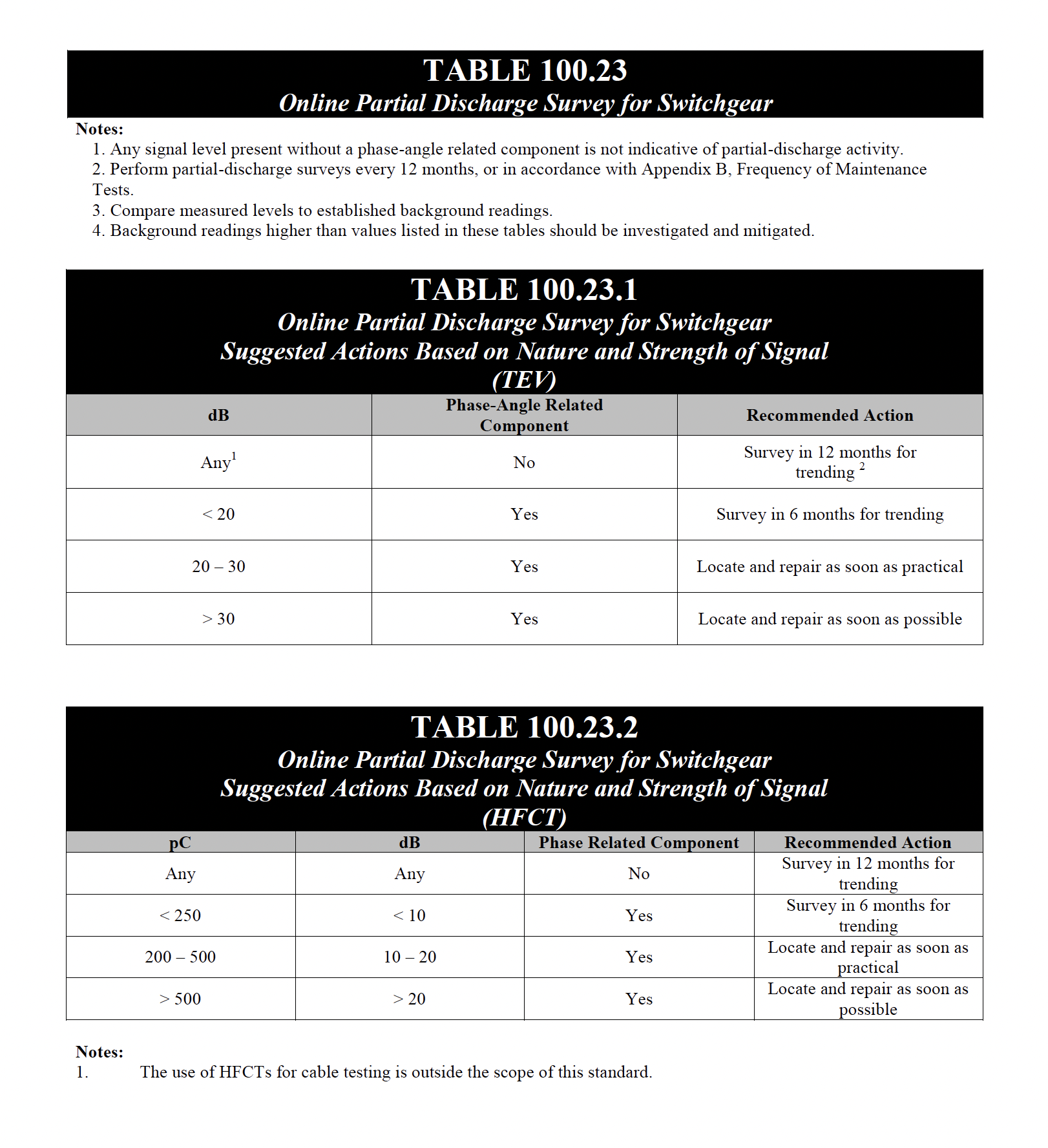

- *Perform online partial-discharge survey in accordance with Section 11.

C.

Test Values – Visual and Mechanical

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of

the lowest value. (7.4.A.3.1)

- Bolt-torque levels should be in accordance with manufacturer’s published data. In the

absence of manufacturer’s published data, use Table 100.12. (7.4.A.3.2)

- Results of the thermographic survey shall be in accordance with Section 9. (7.4.A.3.3)

D.

Test Values – Electrical

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of

the lowest value.

- Insulation-resistance test voltages and resistance values shall be in accordance with

manufacturer’s published data or Table 100.1. In the absence of manufacturer’s published

data, minimum resistance values are for a nominal 1000-foot busway run. Use the following

formula to convert the measured resistance value to the 1000-foot nominal value:

Converted values of insulation resistance less than those in Table 100.1 or manufacturer’s

minimum should be investigated. Dielectric withstand voltage tests shall not proceed until

insulation-resistance levels are raised above minimum values.

- If no evidence of distress or insulation failure is observed by the end of the total time of

voltage application during the dielectric withstand voltage test, the test specimen is

considered to have passed the test.

- Microhm or dc millivolt drop values should not exceed the high levels of the normal range

as indicated in the manufacturer’s published data. If manufacturer’s data is not available,

investigate values which deviate from those of similar bus connections and sections by

more than 50 percent of the lowest value.

- Results of online partial-discharge survey should be in accordance with manufacturer’s

published data. In the absence of manufacturer’s published data, refer to Table 100.23.

|