NETA ATS

Circuit Breakers

NETA ATS

7.6.1.3 Circuit

Breakers, Air, Medium-Voltage

A. Visual and Mechanical

Inspection:

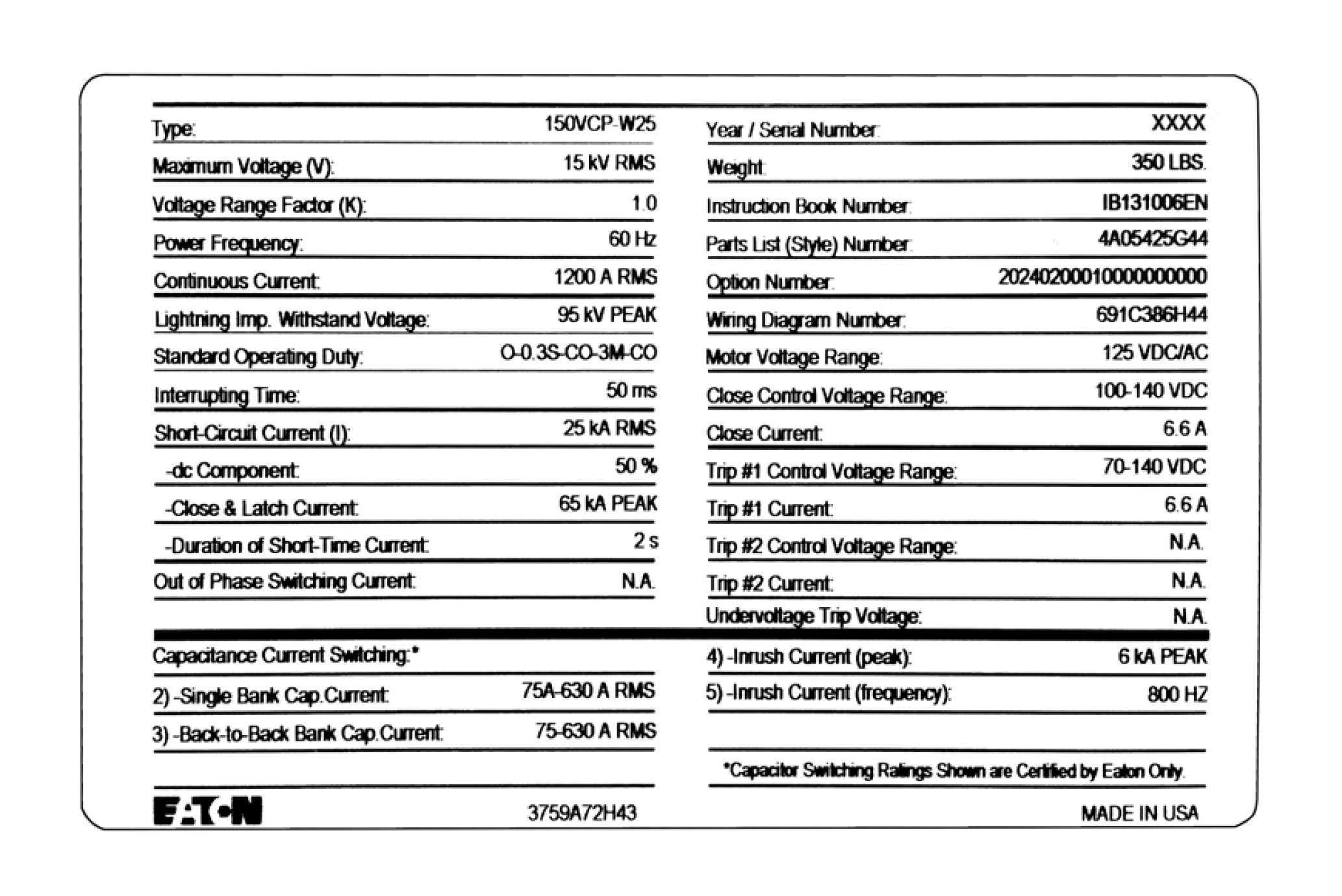

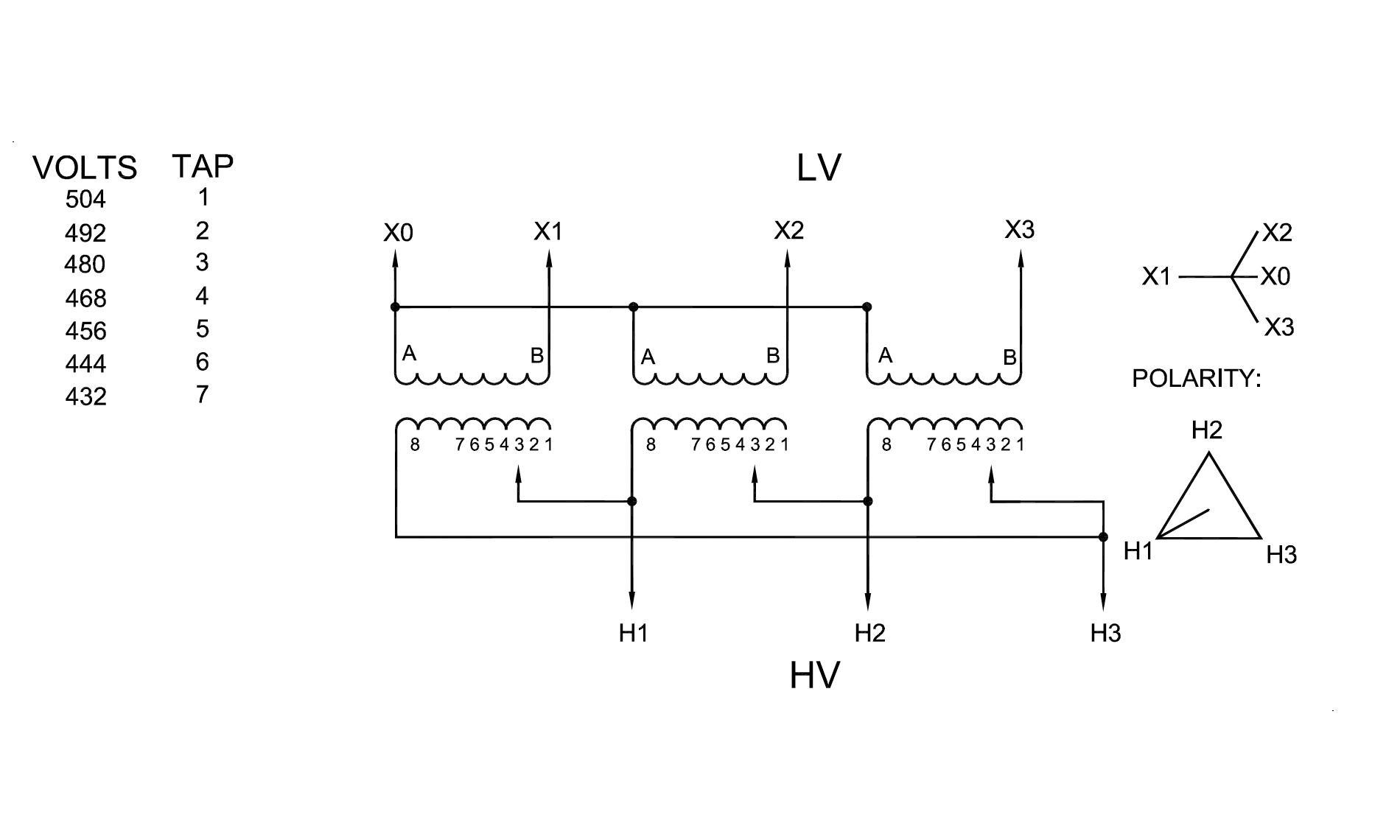

- Compare equipment nameplate data with drawings and specifications

- Inspect physical and mechanical condition.

- Inspect anchorage, alignment, and grounding.

- Verify that all maintenance devices are available for servicing and operating the breaker.

- Verify the unit is clean.

- Verify the arc chutes are intact.

- Inspect moving and stationary contacts for condition and alignment.

- If recommended by manufacturer, slow close/open breaker and check for binding, friction,

contact alignment, and penetration. Verify that contact sequence is in accordance with

manufacturer’s published data. In the absence of manufacturer’s published data, refer to

ANSI/IEEE C37.04.

- Perform all mechanical operation tests on the operating mechanism in accordance with

manufacturer’s published data.

- Inspect bolted electrical connections for high resistance using one or more of the following

methods:

- Use of a low-resistance ohmmeter in accordance with Section 7.6.1.3.B.1.

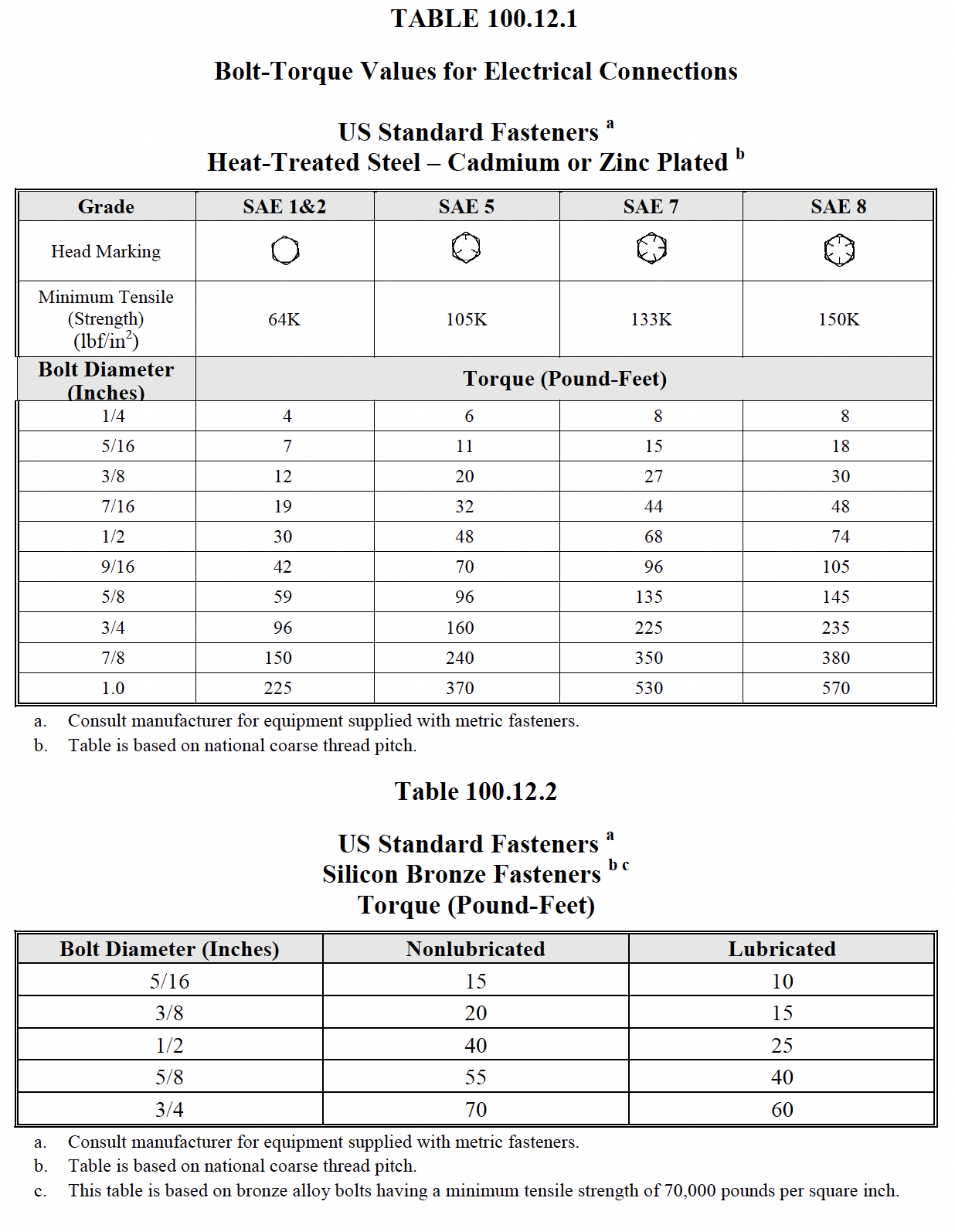

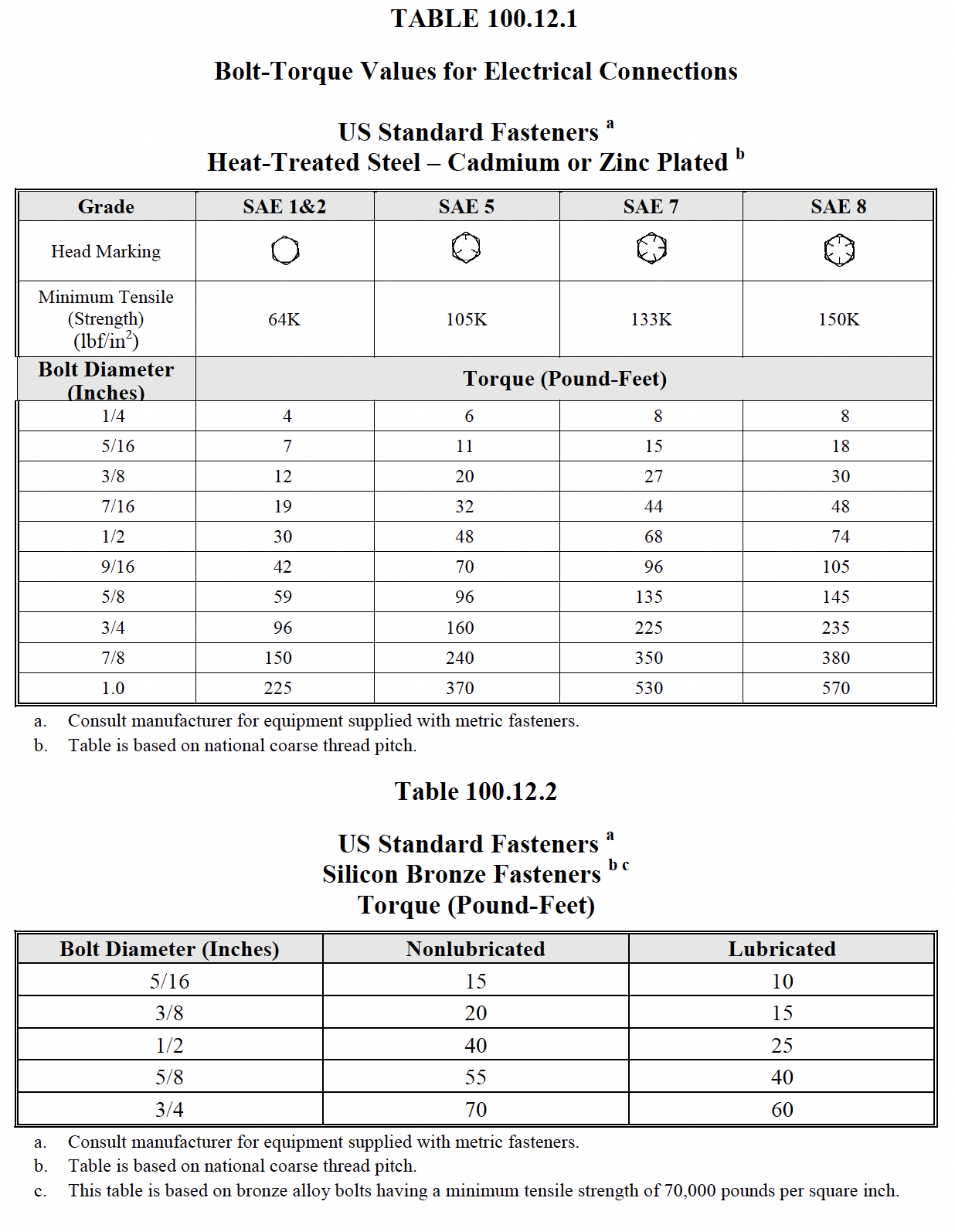

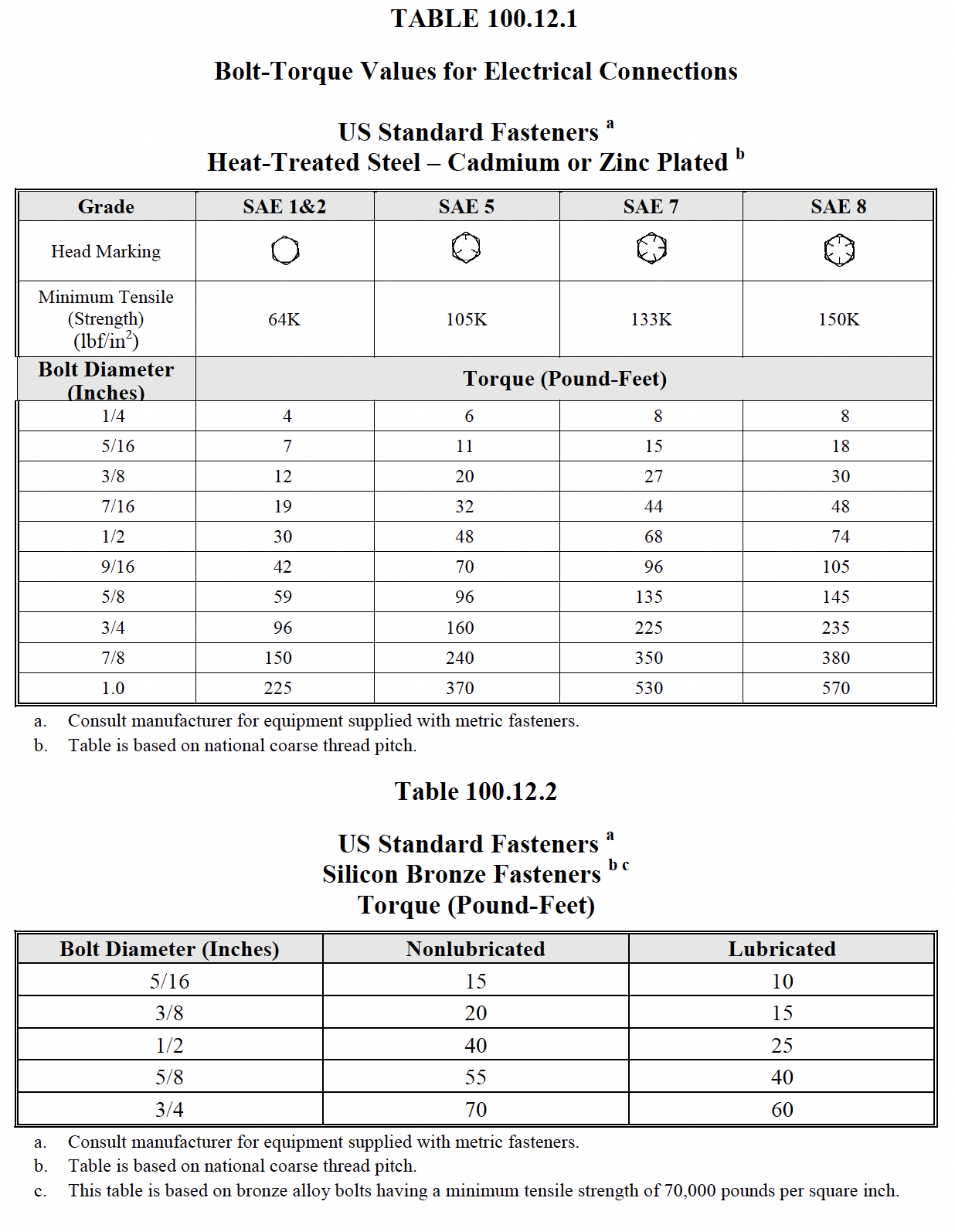

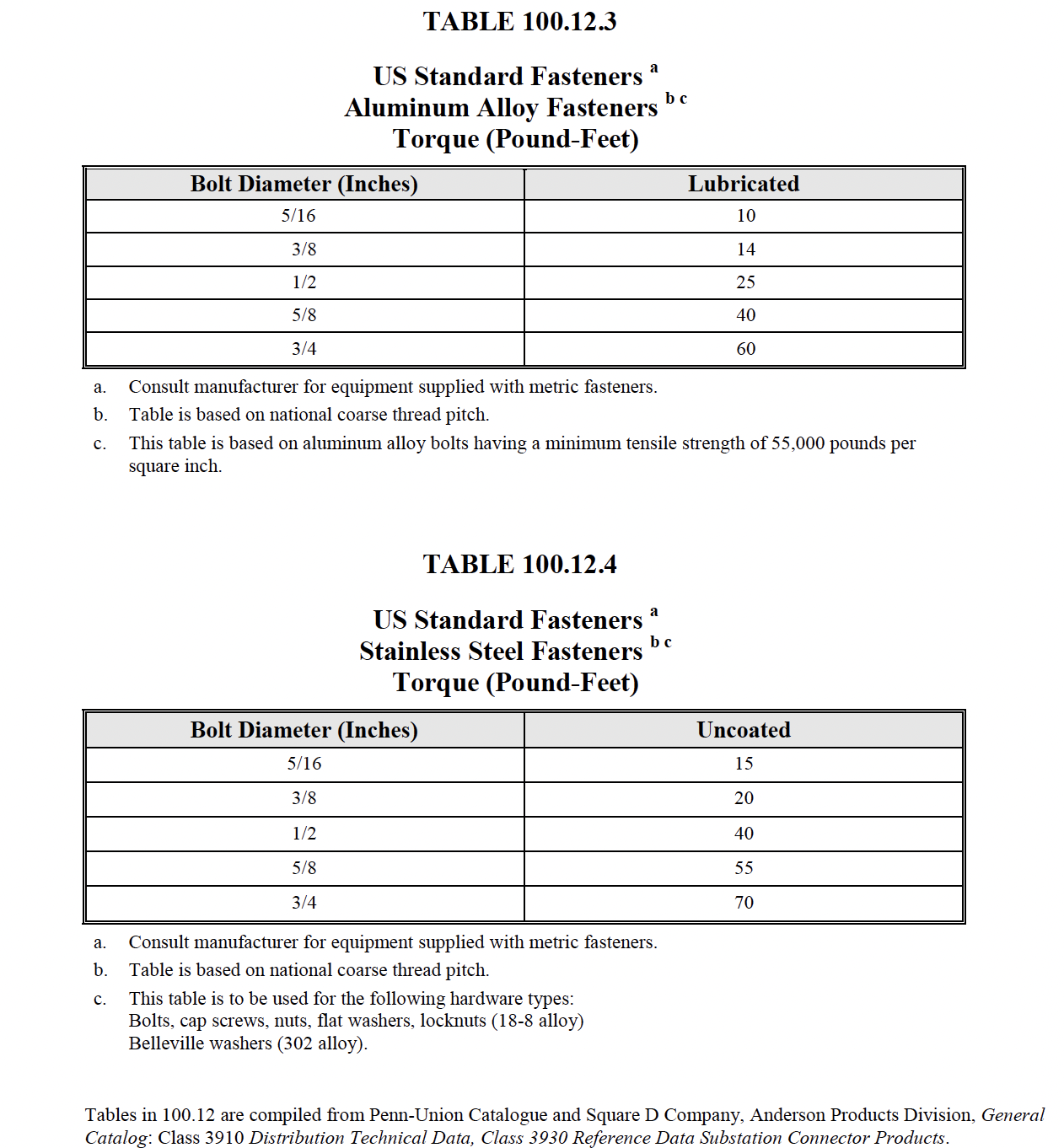

- Verify tightness of accessible bolted electrical connections by calibrated torquewrench

method in accordance with manufacturer’s published data or Table 100.12.

- Perform a thermographic survey in accordance with Section 9.

- verify cell fit and element alignment.

- Verify racking mechanism operation.

- Inspect puffer operation.

- Verify appropriate lubrication on moving current-carrying parts and on moving and sliding

surfaces.

- Perform contact-timing test.

- *Perform mechanism-motion analysis.

- *Perform trip/close coil current signature analysis.

- Record as-found and as-left operation-counter readings.

B. Electrical Tests:

- Perform resistance measurements through bolted connections with a low-resistance

ohmmeter, if applicable. See Section 7.6.1.3.A.10.1.

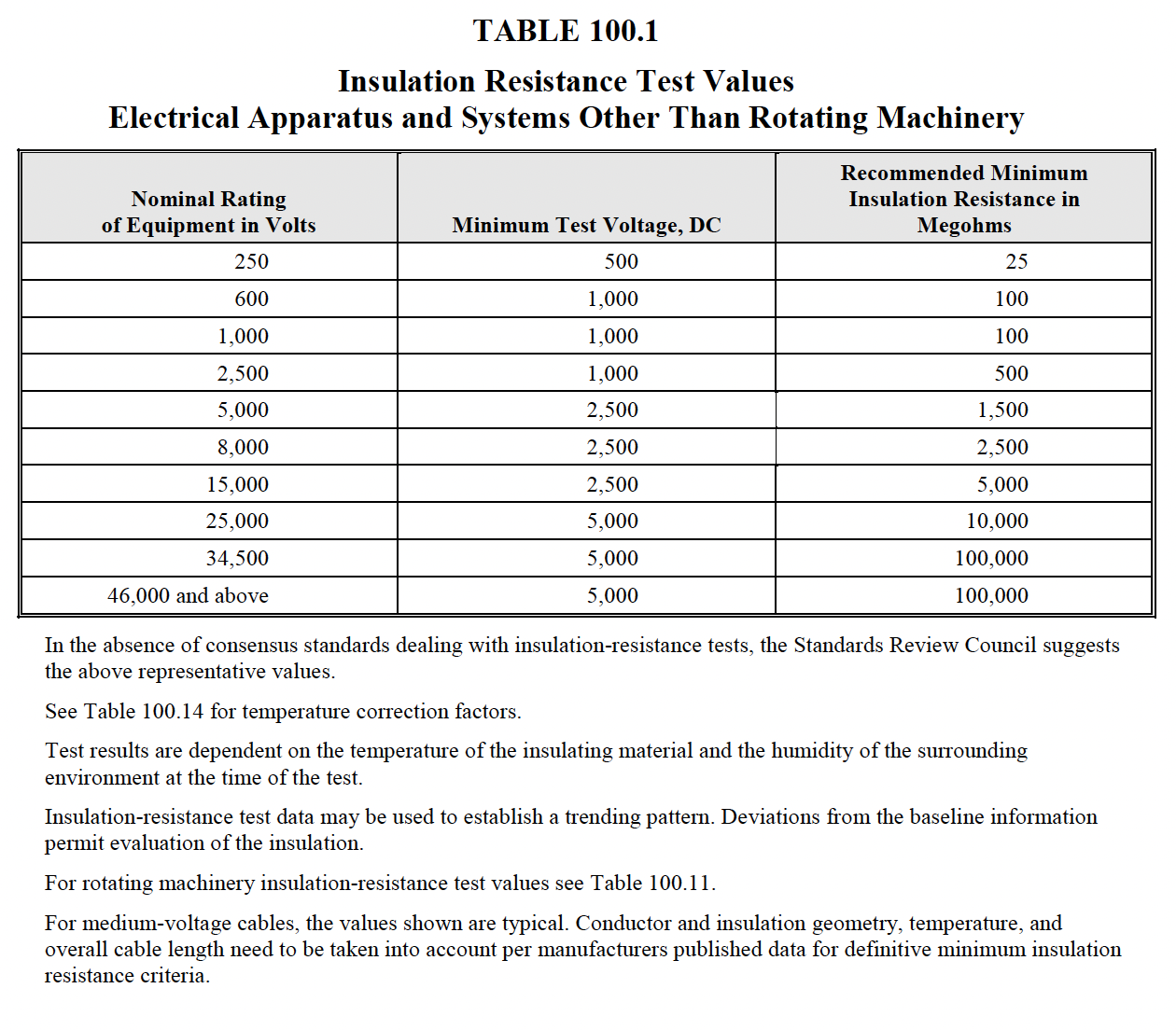

- Perform insulation-resistance tests for one minute on each pole, phase-to-phase and phase-toground

with circuit breaker closed, and across each open pole. Apply voltage in accordance

with manufacturer’s published data. In the absence of manufacturer’s published data, use

Table 100.1.

- Perform a contact/pole-resistance test.

- *Perform insulation-resistance tests on all control wiring with respect to ground. Applied

potential shall be 500 volts dc for 300-volt rated cable and 1000 volts dc for 600-volt rated

cable. Test duration shall be one minute. For units with solid-state components or control

devices that can not tolerate the applied voltage, follow manufacturer’s recommendation.

- With breaker in the test position, make the following tests:

- Trip and close breaker with the control switch.

- Trip breaker by operating each of its protective relays.

- Verify mechanism charge, trip-free, and antipump functions.

- Perform minimum pickup voltage tests on trip and close coils in accordance with

manufacturer’s published data.

- *Perform power-factor or dissipation-factor tests with breaker in both the open and closed

positions.

- *Perform power-factor or dissipation-factor tests on each bushing equipped with a powerfactor/

capacitance tap. In the absence of a power-factor/ capacitance tap, perform hot-collar

tests. These tests shall be in accordance with the test equipment manufacturer’s published

data.

- Perform a dielectric withstand voltage test on each phase with the circuit breaker closed and

the poles not under test grounded. Apply voltage in accordance with manufacturer’s

published data. In the absence of manufacturer’s published data, use Table 100.19.

- Measure blowout coil circuit resistance.

- Verify operation of heaters.

- Test instrument transformers in accordance with Section 7.10.

C. Test Values – Visual and

Mechanical

- Mechanical operation and contact alignment shall be in accordance with manufacturer’s

published data. (7.6.1.3.A.9)

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value. (7.6.1.3.A.10.1)

- Bolt-torque levels shall be in accordance with manufacturer’s published data. In the absence

of manufacturer’s published data, use Table 100.12. (7.6.1.3.A.10.2)

- Results of the thermographic survey shall be in accordance with Section 9. (7.6.1.3.A.10.3)

- Contact timing values shall be in accordance with manufacturer’s published data.

(7.6.1.3.A.15).

- Travel and velocity values shall be in accordance with manufacturer’s published data.

(7.6.1.3.A.16)

- Trip/close coil current values shall be in accordance with manufacturer’s published data.

(7.6.1.3.A.17).

- Operations counter shall advance one digit per close-open cycle. (7.6.1.3.A.18)

D. Test Values – Electrical

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value.

- Insulation-resistance values of circuit breakers shall be in accordance with manufacturer’s

published data. In the absence of manufacturer’s published data, use Table 100.1. Values of

insulation resistance less than this table or manufacturer’s recommendations should be

investigated.

- Microhm or dc millivolt drop values shall not exceed the high levels of the normal range as

indicated in the manufacturer’s published data. In the absence of manufacturer’s published

data, investigate values that deviate from adjacent poles or similar breakers by more than 50

percent of the lowest value.

- Insulation-resistance values of control wiring shall not be less than two megohms.

- Breaker mechanism charge, close, open, trip, trip-free, and antipump features shall function

as designed.

- Minimum pickup voltage of the trip and close coils shall conform to the manufacturer’s

published data. In the absence of the manufacturer’s published data, refer to Table 100.20.

- Power-factor or dissipation-factor values shall be compared with previous test results of

similar breakers or manufacturer’s published data.

- Power-factor or dissipation-factor and capacitance values shall be within ten percent of

nameplate rating for bushings. Hot collar tests are evaluated on a milliampere/milliwatt loss

basis, and the results shall be compared to values of similar bushings.

- If no evidence of distress or insulation failure is observed by the end of the total time of

voltage application during the dielectric withstand test, the circuit breaker is considered to

have passed the test.

- The blowout coil circuit shall exhibit continuity.

- Heaters shall be operational.

- The results of instrument transformer tests shall be in accordance with Section 7.10.

NETA ATS

7.6.3 Circuit

Breakers, Vacuum, Medium-Voltage

A. Visual and Mechanical

Inspection:

- Compare equipment nameplate data with drawings and specifications.

- Inspect physical and mechanical condition.

- Inspect anchorage, alignment, and grounding.

- Verify that all maintenance devices such as special tools and gauges specified by the

manufacturer are available for servicing and operating the breaker.

- Verify the unit is clean.

- Perform all mechanical operation tests on the operating mechanism in accordance with

manufacturer’s published data.

- Measure critical distances such as contact gap as recommended by manufacturer.

- Inspect bolted electrical connections for high resistance using one or more of the following

methods:

- Use of low-resistance ohmmeter in accordance with Section 7.6.3.B.1.

- Verify tightness of accessible bolted electrical connections by calibrated torquewrench

method in accordance with manufacturer’s published data or Table 100.12.

- Perform thermographic survey in accordance with Section 9.

- Verify cell fit and element alignment.

- Verify racking mechanism operation.

- Verify appropriate lubrication on moving, current-carrying parts and on moving and sliding

surfaces.

- Perform contact-timing test.

- *Perform trip/close coil current signature analysis.

- *Perform mechanism motion analysis.

- Record as-found and as-left operation counter readings.

B. Electrical Tests:

- Perform resistance measurements through bolted connections with a low-resistance

ohmmeter, if applicable, in accordance with Section 7.6.3.A.8.1.

- Perform insulation-resistance tests for one minute on each pole, phase-to-phase and phase-toground

with the circuit breaker closed, and across each open pole. Test voltage shall be in

accordance with manufacturer’s published data. In the absence of manufacturer’s published

data, use Table 100.1.

- *Perform insulation-resistance tests on all control wiring with respect to ground. Applied

potential shall be 500 volts dc for 300-volt rated cable and 1000 volts dc for 600-volt rated

cable. Test duration shall be one minute. For units with solid-state components, follow

manufacturer’s recommendation.

- *Perform dynamic contact/pole resistance test.

- Perform minimum pickup voltage tests on trip and close coils in accordance with

manufacturer’s published data.

- Verify correct operation of any auxiliary features such as electrical close and trip operation,

trip-free, and antipump function.

- Trip circuit breaker by operation of each protective device. Reset all trip logs and indicators.

- *Perform power-factor or dissipation-factor tests on each pole with the breaker open and each

phase with the breaker closed.

- *Perform power-factor or dissipation-factor tests on each bushing equipped with a powerfactor/

capacitance tap. In the absence of a power-factor/ capacitance tap, perform hot-collar

tests. These tests shall be in accordance with the test equipment manufacturer’s published

data.

- *Perform magnetron atmospheric condition (MAC) test on each vacuum interrupter.

- Perform vacuum bottle integrity (dielectric withstand voltage) test across each vacuum bottle

with the breaker in the open position in strict accordance with manufacturer’s published data.

- Perform a dielectric withstand voltage test in accordance with manufacturer’s published data.

- Verify operation of heaters.

- Test instrument transformers in accordance with Section 7.10.

C. Test Values – Visual and

Mechanical

- Critical distance measurements such as contact gap shall be in accordance with the

manufacturer’s published data. (7.6.3.A.7)

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value. (7.6.3.A.8.1)

- Bolt-torque levels shall be in accordance with manufacturer’s published data. In the absence

of manufacturer’s published data, use Table 100.12. (7.6.3.A.8.2)

- Results of the thermographic survey shall be in accordance with Section 9. (7.6.3.A.8.3)

- Contact timing values shall be in accordance with manufacturer’s published data.

(7.6.3.A.12)

- Trip/close coil current values shall be in accordance with manufacturer’s published data.

(7.6.3.A.13)

- Travel and velocity values shall be in accordance with manufacturer’s published data.

(7.6.3.A.14)

- Operation counter shall advance one digit per close-open cycle. (7.6.3.A.15)

-

D. Test Values – Electrical

<

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value.

- Insulation-resistance values of circuit breakers shall be in accordance with manufacturer’s

published data. In the absence of manufacturer’s published data, use Table 100.1. Values of

insulation resistance less than this table or manufacturer’s recommendations should be

investigated.

- Insulation-resistance values of control wiring shall not be less than two megohms.

- Microhm or dc millivolt drop values shall not exceed the high levels of the normal range as

indicated in the manufacturer’s published data. In the absence of manufacturer’s published

data, investigate values that deviate from adjacent poles or similar breakers by more than 50

percent of the lowest value.

- Dynamic contact resistance values shall be in accordance with manufacturer’s published data.

- Minimum pickup voltage of the trip and close coils shall conform to the manufacturer’s

published data. In the absence of the manufacturer’s published data, refer to Table 100.20.

- Auxiliary features shall operate in accordance with manufacturer’s published data.

- Protective devices shall operate the breaker per system design.

- Power-factor or dissipation-factor values shall be compared to manufacturer’s published data.

In the absence of manufacturer’s published data the comparison shall be made to similar

breakers.

- Power-factor or dissipation-factor and capacitance values shall be within ten percent of

nameplate rating for bushings. Hot collar tests are evaluated on a milliampere/milliwatt loss

basis, and the results should be compared to values of similar bushings.

- Evaluate each vacuum interrupter in accordance with test equipment manufacturer’s

instructions.

- If no evidence of distress or insulation failure is observed by the end of the total time of

voltage application during the dielectric withstand test, the test specimen is considered to

have passed the test.

- Heaters shall be operational.

- Results of instrument transformer tests shall be in accordance with Section 7.10.

NETA ATS

7.6.2 Circuit

Breakers, Oil, Medium- and High-Voltage

A. Visual and Mechanical

Inspection:

- Compare equipment nameplate data with drawings and specifications.

- Inspect physical and mechanical condition.

- Inspect anchorage, alignment, grounding, and required clearances.

- Verify that all maintenance devices such as special tools and gauges specified by the

manufacturer are available for servicing and operating the breaker.

- Verify correct oil level in all tanks and bushings.

- Verify that breather vents are clear.

- Verify the unit is clean.

- Inspect hydraulic system and air compressor in accordance with manufacturer’s published

data.

- Test alarms and pressure-limit switches for pneumatic and hydraulic operators as

recommended by the manufacturer.

- Perform mechanical operation tests on the operating mechanism in accordance with

manufacturer’s published data.

- While performing internal inspection:

- Remove oil. Lower tanks or remove manhole covers as necessary. Inspect bottom of

tank for broken parts and debris.

- Inspect lift rod and toggle assemblies, contacts, interrupters, bumpers, dashpots,

bushing current transformers, tank liners, and gaskets.

- Verify that contact sequence is in accordance with manufacturer’s published data. In

the absence of manufacturer’s published data, refer to ANSI/IEEE C37.04.

- Fill tank(s) with filtered oil.

- Inspect bolted electrical connections for high resistance using one or more of the following

methods:

- Use of low-resistance ohmmeter in accordance with Section 7.6.2.B.1.

- Verify tightness of accessible bolted electrical connections by calibrated torquewrench

method in accordance with manufacturer’s published data or Table 100.12.

- Perform thermographic survey in accordance with Section 9.

- Verify cell fit and element alignment, if applicable.

- Verify racking mechanism operation, if applicable.

- Perform contact-timing test.

- Perform mechanism-motion analysis.

- *Perform trip/close coil current signature analysis.

- Verify appropriate lubrication on moving current-carrying parts and on moving and sliding

surfaces.

- Record as-found and as-left operation counter readings.

B. Electrical Tests:

- Perform resistance measurements through bolted connections with a low-resistance

ohmmeter, if applicable, in accordance with Section 7.6.2.A.12.1

- Perform insulation-resistance tests for one minute on each pole, phase-to-phase and phase-toground

with circuit-breaker closed, and across each open pole. Test voltage shall be in

accordance with manufacturer’s published data. In the absence of manufacturer’s published

data, use Table 100.1.

- Perform a static contact/pole resistance test.

- *Perform a dynamic contact/pole resistance test.

- *Perform insulation-resistance tests on all control wiring with respect to ground. Applied

potential shall be 500 volts dc for 300-volt rated cable and 1000 volts dc for 600-volt rated

cable. Test duration shall be one minute. For units with solid-state components, follow

manufacturer’s recommendation.

- Remove a sample of insulating liquid in accordance with ASTM D 923. Sample shall be

tested in accordance with the referenced standard.

- Dielectric breakdown voltage: ASTM D 877

- Color: ANSI/ASTM D 1500

- Power factor: ASTM D 924

- Interfacial tension: ASTM D 971

- Visual condition: ASTM D 1524

- Neutralization number (acidity): ASTM D974

- Water content: ASTM D1533

- Perform minimum pickup voltage tests on trip and close coils in accordance with

manufacturer’s published data.

- Verify correct operation of any auxiliary features such as electrical close and trip operation,

trip-free, antipump function.

- Trip circuit breaker by operation of each protective device. Reset all trip logs and indicators.

- Perform power-factor or dissipation-factor tests on each pole with breaker open and each

phase with breaker closed. Determine tank loss index.

- Perform power-factor or dissipation-factor tests on each bushing equipped with a powerfactor/

capacitance tap. In the absence of a power-factor/ capacitance tap, perform hot-collar

tests. These tests shall be in accordance with the test equipment manufacturer’s published

data.

- *Perform a dielectric withstand voltage test in accordance with manufacturer’s published data.

- Verify operation of heaters.

- Test instrument transformers in accordance with Section 7.10.

C. Test Values – Visual and

Mechanical

- Settings for alarm, pressure, and limit switches shall be in accordance with owner’s

specifications. In the absence of owner’s specifications use manufacturer’s published data.

(7.6.2.A.9)

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value. (7.6.2.A.12.1)

- Bolt-torque levels shall be in accordance with manufacturer’s published data. In the absence

of manufacturer’s published data, use Table 100.12. (7.6.2.A.12.2)

- Results of the thermographic survey shall be in accordance with Section 9. (7.6.2.A.12.3)

- Contact timing values shall be in accordance with manufacturer’s published data.

(7.6.2.A.15).

- Travel and velocity values shall be in accordance with manufacturer’s published data.

(7.6.2.A.16)

- Trip/close coil current values shall be in accordance with manufacturer’s published data.

(7.6.2.A.17).

- Operations counter shall advance one digit per close-open cycle. (7.6.2.A.19)

D. Test Values – Electrical

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value.

- Insulation-resistance values of circuit breakers shall be in accordance with manufacturer’s

published data. In the absence of manufacturer’s published data, use Table 100.1. Values of

insulation resistance less than this table or manufacturer’s recommendations should be

investigated.

- Microhm or dc millivolt drop values shall not exceed the high levels of the normal range as

indicated in the manufacturer’s published data. If manufacturer’s published data is not

available, investigate values that deviate from adjacent poles or similar breakers by more than

50 percent of the lowest value.

- Dynamic contact resistance values shall be in accordance with manufacturer’s published data.

- Insulation-resistance values of control wiring shall not be less than two megohms.

- Insulating liquid test results shall be in accordance with Table 100.4.

- Minimum pickup voltage of the trip and close coils shall conform to the manufacturer’s

published data. In the absence of the manufacturer’s published data, refer to Table 100.20.

- Auxiliary features shall operate in accordance with manufacturer’s published data.

- Protective devices shall operate the breaker per system design.

- Power-factor or dissipation-factor values and tank loss index shall be compared to

manufacturer’s published data. In the absence of manufacturer’s published data, the

comparison shall be made to test data from similar breakers or data from test equipment

manufacturers.

- Power-factor or dissipation-factor and capacitance values shall be within ten percent of

nameplate rating for bushings. Hot collar tests are evaluated on a milliampere/milliwatt loss

basis, and the results should be compared to values of similar bushings.

- If no evidence of distress or insulation failure is observed by the end of the total time of

voltage application during the dielectric withstand test, the test specimen is considered to

have passed the test.

- Heaters shall be operational.

- Results of electrical tests on instrument transformers shall be in accordance with Section

7.10.

NETA ATS

7.6.4 Circuit

Breakers, SF6

A. Visual and Mechanical

Inspection:

- Compare equipment nameplate data with drawings and specifications.

- Inspect physical and mechanical condition.

- Inspect anchorage, alignment, and grounding.

- Verify that all maintenance devices such as special tools and gauges specified by the

manufacturer are available for servicing and operating the breaker.

- Verify the unit is clean.

- When provisions are made for sampling, remove a sample of SF6 gas and test in accordance

with Table 100.13. Do not break seal or distort “sealed-for-life” interrupters.

- Inspect operating mechanism and/or hydraulic or pneumatic system and SF6 gas-insulated

system in accordance with manufacturer’s published data.

- Test for SF6 gas leaks in accordance with manufacturer’s published data.

- Verify correct operation of alarms and pressure-limit switches for pneumatic, hydraulic, and

SF6 gas pressure in accordance with manufacturer’s published data.

- If recommended by manufacturer, slow close/open breaker and check for binding, friction,

contact alignment, and penetration. Verify that contact sequence is in accordance with

manufacturer’s published data. In the absence of manufacturer’s published data, refer to

ANSI/IEEE C37.04.

- Perform all mechanical operation tests on the operating mechanism in accordance with the

manufacturer’s published data.

- Inspect all bolted electrical connections for high resistance using one or more of the

following methods:

- Use of a low-resistance ohmmeter in accordance with Section 7.6.4.B.1.

- Verify tightness of accessible bolted electrical connections by calibrated torquewrench

method in accordance with manufacturer’s published data or Table 100.12.

- Perform a thermographic survey in accordance with Section 9.

- Verify the appropriate lubrication on moving current-carrying parts and on moving and

sliding surfaces.

- Perform contact-timing test.

- *Perform trip/close coil signature analysis.

- Perform mechanism motion analysis.

- Record as-found and as-left operation counter readings.

B. Electrical Tests:

- Perform resistance measurements through all bolted connections with a low-resistance

ohmmeter, if applicable, in accordance with Section 7.6.4.A.12.1.

- Perform insulation-resistance tests in accordance with Table 100.1 from each pole-to-ground

with breaker closed and across open poles at each phase. For single-tank breakers, perform

insulation resistance tests in accordance with Table 100.1 from pole-to-pole.

- Perform a contact/pole-resistance test.

- *Perform insulation-resistance tests on all control wiring with respect to ground. Applied

potential shall be 500 volts dc for 300-volt rated cable and 1000 volts dc for 600-volt rated

cable. Test duration shall be one minute. For units with solid-state components or for control

devices that cannot tolerate the voltage, follow manufacturer’s recommendation.

- Perform minimum pickup voltage tests on trip and close coils in accordance with

manufacturer’s published data.

- Verify correct operation of any auxiliary features such as electrical close and trip operation,

trip-free, and antipump function. Reset all trip logs and indicators.

- Trip circuit breaker by operation of each protective device.

- Perform power-factor or dissipation-factor tests on each pole with the breaker open and on

each phase with the breaker closed.

- Perform power-factor or dissipation-factor tests on each bushing equipped with a powerfactor/

capacitance tap. In the absence of a power-factor/ capacitance tap, perform hot-collar

tests. These tests shall be in accordance with the test equipment manufacturer’s published

data.

- *Perform a dielectric withstand voltage test in accordance with manufacturer’s published data.

- Verify operation of heaters.

- Test instrument transformers in accordance with Section 7.10.

C. Test Values – Visual and

Mechanical

-

- SF6 gas shall have values in accordance with Table 100.13. (7.6.4.A.6)

- Results of the SF6 gas leak test shall confirm that no SF6 gas leak exists. (7.6.4.A.8)

- Settings for alarm, pressure, and limit switches shall be in accordance with manufacturer’s

published data. (7.6.4.A.9)

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value. (7.6.4.A.12.1)

- Bolt-torque levels shall be in accordance with manufacturer’s published data. In the absence

of manufacturer’s published data, use Table 100.12. (7.6.4.A.12.2)

- Results of the thermographic survey shall be in accordance with Section 9. (7.6.4.A.12.3)

- Contact timing values shall be in accordance with manufacturer’s published data.

(7.6.4.A.14)

- Trip/close coil current values shall be in accordance with manufacturer’s published data

(7.6.4.A.15)

- Travel and velocity values shall be in accordance with manufacturer’s published data.

(7.6.4.A.16)

- Operations counter shall advance one digit per close-open cycle. (7.6.4.A.17)

D. Test Values – Electrical

-

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value.

- Insulation-resistance values of circuit breakers shall be in accordance with manufacturer’s

published data. In the absence of manufacturer’s published data, use Table 100.1. Values of

insulation resistance less than this table or manufacturer’s recommendations should be

investigated.

- Microhm or dc millivolt drop values shall not exceed the high levels of the normal range as

indicated in the manufacturer’s published data. In the absence of manufacturer’s published

data, investigate values that deviate from adjacent poles or similar breakers by more than 50

percent of the lowest value.

- Insulation-resistance values of control wiring shall not be less than two megohms.

- Minimum pickup voltage of the trip and close coils shall conform to the manufacturer’s

published data. In the absence of the manufacturer’s published data, refer to Table 100.20.

- Auxiliary features shall operate in accordance with manufacturer’s published data.

- Protective devices shall operate the breaker per the system design.

- Power-factor or dissipation-factor values shall be compared to manufacturer’s published data.

In the absence of manufacturer’s published data, the comparison shall be made to test data

from similar breakers or data from test equipment manufacturers.

- Power-factor or dissipation-factor and capacitance test values shall be within ten percent of

nameplate rating for bushings. Hot collar tests are evaluated on a milliampere/milliwatt loss

basis, and the results shall be compared to values of similar bushings.

- If no evidence of distress or insulation failure is observed by the end of the total time of

voltage application during the dielectric withstand test, the test specimen is considered to

have passed the test.

- Heaters shall be operational.

- Results of electrical tests on instrument transformers shall be in accordance with Section

7.10.

NETA ATS

7.6.1.3 Circuit

Breakers, Air, Medium-Voltage

A. Visual and Mechanical

Inspection:

- Compare equipment nameplate data with drawings and specifications

- Inspect physical and mechanical condition.

- Inspect anchorage, alignment, and grounding.

- Verify that all maintenance devices are available for servicing and operating the breaker.

- Verify the unit is clean.

- Verify the arc chutes are intact.

- Inspect moving and stationary contacts for condition and alignment.

- If recommended by manufacturer, slow close/open breaker and check for binding, friction,

contact alignment, and penetration. Verify that contact sequence is in accordance with

manufacturer’s published data. In the absence of manufacturer’s published data, refer to

ANSI/IEEE C37.04.

- Perform all mechanical operation tests on the operating mechanism in accordance with

manufacturer’s published data.

- Inspect bolted electrical connections for high resistance using one or more of the following

methods:

- Use of a low-resistance ohmmeter in accordance with Section 7.6.1.3.B.1.

- Verify tightness of accessible bolted electrical connections by calibrated torquewrench

method in accordance with manufacturer’s published data or Table 100.12.

- Perform a thermographic survey in accordance with Section 9.

- verify cell fit and element alignment.

- Verify racking mechanism operation.

- Inspect puffer operation.

- Verify appropriate lubrication on moving current-carrying parts and on moving and sliding

surfaces.

- Perform contact-timing test.

- *Perform mechanism-motion analysis.

- *Perform trip/close coil current signature analysis.

- Record as-found and as-left operation-counter readings.

B. Electrical Tests:

- Perform resistance measurements through bolted connections with a low-resistance

ohmmeter, if applicable. See Section 7.6.1.3.A.10.1.

- Perform insulation-resistance tests for one minute on each pole, phase-to-phase and phase-toground

with circuit breaker closed, and across each open pole. Apply voltage in accordance

with manufacturer’s published data. In the absence of manufacturer’s published data, use

Table 100.1.

- Perform a contact/pole-resistance test.

- *Perform insulation-resistance tests on all control wiring with respect to ground. Applied

potential shall be 500 volts dc for 300-volt rated cable and 1000 volts dc for 600-volt rated

cable. Test duration shall be one minute. For units with solid-state components or control

devices that can not tolerate the applied voltage, follow manufacturer’s recommendation.

- With breaker in the test position, make the following tests:

- Trip and close breaker with the control switch.

- Trip breaker by operating each of its protective relays.

- Verify mechanism charge, trip-free, and antipump functions.

- Perform minimum pickup voltage tests on trip and close coils in accordance with

manufacturer’s published data.

- *Perform power-factor or dissipation-factor tests with breaker in both the open and closed

positions.

- *Perform power-factor or dissipation-factor tests on each bushing equipped with a powerfactor/

capacitance tap. In the absence of a power-factor/ capacitance tap, perform hot-collar

tests. These tests shall be in accordance with the test equipment manufacturer’s published

data.

- Perform a dielectric withstand voltage test on each phase with the circuit breaker closed and

the poles not under test grounded. Apply voltage in accordance with manufacturer’s

published data. In the absence of manufacturer’s published data, use Table 100.19.

- Measure blowout coil circuit resistance.

- Verify operation of heaters.

- Test instrument transformers in accordance with Section 7.10.

C. Test Values – Visual and

Mechanical

- Mechanical operation and contact alignment shall be in accordance with manufacturer’s

published data. (7.6.1.3.A.9)

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value. (7.6.1.3.A.10.1)

- Bolt-torque levels shall be in accordance with manufacturer’s published data. In the absence

of manufacturer’s published data, use Table 100.12. (7.6.1.3.A.10.2)

- Results of the thermographic survey shall be in accordance with Section 9. (7.6.1.3.A.10.3)

- Contact timing values shall be in accordance with manufacturer’s published data.

(7.6.1.3.A.15).

- Travel and velocity values shall be in accordance with manufacturer’s published data.

(7.6.1.3.A.16)

- Trip/close coil current values shall be in accordance with manufacturer’s published data.

(7.6.1.3.A.17).

- Operations counter shall advance one digit per close-open cycle. (7.6.1.3.A.18)

D. Test Values – Electrical

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value.

- Insulation-resistance values of circuit breakers shall be in accordance with manufacturer’s

published data. In the absence of manufacturer’s published data, use Table 100.1. Values of

insulation resistance less than this table or manufacturer’s recommendations should be

investigated.

- Microhm or dc millivolt drop values shall not exceed the high levels of the normal range as

indicated in the manufacturer’s published data. In the absence of manufacturer’s published

data, investigate values that deviate from adjacent poles or similar breakers by more than 50

percent of the lowest value.

- Insulation-resistance values of control wiring shall not be less than two megohms.

- Breaker mechanism charge, close, open, trip, trip-free, and antipump features shall function

as designed.

- Minimum pickup voltage of the trip and close coils shall conform to the manufacturer’s

published data. In the absence of the manufacturer’s published data, refer to Table 100.20.

- Power-factor or dissipation-factor values shall be compared with previous test results of

similar breakers or manufacturer’s published data.

- Power-factor or dissipation-factor and capacitance values shall be within ten percent of

nameplate rating for bushings. Hot collar tests are evaluated on a milliampere/milliwatt loss

basis, and the results shall be compared to values of similar bushings.

- If no evidence of distress or insulation failure is observed by the end of the total time of

voltage application during the dielectric withstand test, the circuit breaker is considered to

have passed the test.

- The blowout coil circuit shall exhibit continuity.

- Heaters shall be operational.

- The results of instrument transformer tests shall be in accordance with Section 7.10.

NETA ATS

7.6.3 Circuit

Breakers, Vacuum, Medium-Voltage

A. Visual and Mechanical

Inspection:

- Compare equipment nameplate data with drawings and specifications.

- Inspect physical and mechanical condition.

- Inspect anchorage, alignment, and grounding.

- Verify that all maintenance devices such as special tools and gauges specified by the

manufacturer are available for servicing and operating the breaker.

- Verify the unit is clean.

- Perform all mechanical operation tests on the operating mechanism in accordance with

manufacturer’s published data.

- Measure critical distances such as contact gap as recommended by manufacturer.

- Inspect bolted electrical connections for high resistance using one or more of the following

methods:

- Use of low-resistance ohmmeter in accordance with Section 7.6.3.B.1.

- Verify tightness of accessible bolted electrical connections by calibrated torquewrench

method in accordance with manufacturer’s published data or Table 100.12.

- Perform thermographic survey in accordance with Section 9.

- Verify cell fit and element alignment.

- Verify racking mechanism operation.

- Verify appropriate lubrication on moving, current-carrying parts and on moving and sliding

surfaces.

- Perform contact-timing test.

- *Perform trip/close coil current signature analysis.

- *Perform mechanism motion analysis.

- Record as-found and as-left operation counter readings.

B. Electrical Tests:

- Perform resistance measurements through bolted connections with a low-resistance

ohmmeter, if applicable, in accordance with Section 7.6.3.A.8.1.

- Perform insulation-resistance tests for one minute on each pole, phase-to-phase and phase-toground

with the circuit breaker closed, and across each open pole. Test voltage shall be in

accordance with manufacturer’s published data. In the absence of manufacturer’s published

data, use Table 100.1.

- *Perform insulation-resistance tests on all control wiring with respect to ground. Applied

potential shall be 500 volts dc for 300-volt rated cable and 1000 volts dc for 600-volt rated

cable. Test duration shall be one minute. For units with solid-state components, follow

manufacturer’s recommendation.

- *Perform dynamic contact/pole resistance test.

- Perform minimum pickup voltage tests on trip and close coils in accordance with

manufacturer’s published data.

- Verify correct operation of any auxiliary features such as electrical close and trip operation,

trip-free, and antipump function.

- Trip circuit breaker by operation of each protective device. Reset all trip logs and indicators.

- *Perform power-factor or dissipation-factor tests on each pole with the breaker open and each

phase with the breaker closed.

- *Perform power-factor or dissipation-factor tests on each bushing equipped with a powerfactor/

capacitance tap. In the absence of a power-factor/ capacitance tap, perform hot-collar

tests. These tests shall be in accordance with the test equipment manufacturer’s published

data.

- *Perform magnetron atmospheric condition (MAC) test on each vacuum interrupter.

- Perform vacuum bottle integrity (dielectric withstand voltage) test across each vacuum bottle

with the breaker in the open position in strict accordance with manufacturer’s published data.

- Perform a dielectric withstand voltage test in accordance with manufacturer’s published data.

- Verify operation of heaters.

- Test instrument transformers in accordance with Section 7.10.

C. Test Values – Visual and

Mechanical

- Critical distance measurements such as contact gap shall be in accordance with the

manufacturer’s published data. (7.6.3.A.7)

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value. (7.6.3.A.8.1)

- Bolt-torque levels shall be in accordance with manufacturer’s published data. In the absence

of manufacturer’s published data, use Table 100.12. (7.6.3.A.8.2)

- Results of the thermographic survey shall be in accordance with Section 9. (7.6.3.A.8.3)

- Contact timing values shall be in accordance with manufacturer’s published data.

(7.6.3.A.12)

- Trip/close coil current values shall be in accordance with manufacturer’s published data.

(7.6.3.A.13)

- Travel and velocity values shall be in accordance with manufacturer’s published data.

(7.6.3.A.14)

- Operation counter shall advance one digit per close-open cycle. (7.6.3.A.15)

-

D. Test Values – Electrical

<

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value.

- Insulation-resistance values of circuit breakers shall be in accordance with manufacturer’s

published data. In the absence of manufacturer’s published data, use Table 100.1. Values of

insulation resistance less than this table or manufacturer’s recommendations should be

investigated.

- Insulation-resistance values of control wiring shall not be less than two megohms.

- Microhm or dc millivolt drop values shall not exceed the high levels of the normal range as

indicated in the manufacturer’s published data. In the absence of manufacturer’s published

data, investigate values that deviate from adjacent poles or similar breakers by more than 50

percent of the lowest value.

- Dynamic contact resistance values shall be in accordance with manufacturer’s published data.

- Minimum pickup voltage of the trip and close coils shall conform to the manufacturer’s

published data. In the absence of the manufacturer’s published data, refer to Table 100.20.

- Auxiliary features shall operate in accordance with manufacturer’s published data.

- Protective devices shall operate the breaker per system design.

- Power-factor or dissipation-factor values shall be compared to manufacturer’s published data.

In the absence of manufacturer’s published data the comparison shall be made to similar

breakers.

- Power-factor or dissipation-factor and capacitance values shall be within ten percent of

nameplate rating for bushings. Hot collar tests are evaluated on a milliampere/milliwatt loss

basis, and the results should be compared to values of similar bushings.

- Evaluate each vacuum interrupter in accordance with test equipment manufacturer’s

instructions.

- If no evidence of distress or insulation failure is observed by the end of the total time of

voltage application during the dielectric withstand test, the test specimen is considered to

have passed the test.

- Heaters shall be operational.

- Results of instrument transformer tests shall be in accordance with Section 7.10.

NETA ATS

7.6.2 Circuit

Breakers, Oil, Medium- and High-Voltage

A. Visual and Mechanical

Inspection:

- Compare equipment nameplate data with drawings and specifications.

- Inspect physical and mechanical condition.

- Inspect anchorage, alignment, grounding, and required clearances.

- Verify that all maintenance devices such as special tools and gauges specified by the

manufacturer are available for servicing and operating the breaker.

- Verify correct oil level in all tanks and bushings.

- Verify that breather vents are clear.

- Verify the unit is clean.

- Inspect hydraulic system and air compressor in accordance with manufacturer’s published

data.

- Test alarms and pressure-limit switches for pneumatic and hydraulic operators as

recommended by the manufacturer.

- Perform mechanical operation tests on the operating mechanism in accordance with

manufacturer’s published data.

- While performing internal inspection:

- Remove oil. Lower tanks or remove manhole covers as necessary. Inspect bottom of

tank for broken parts and debris.

- Inspect lift rod and toggle assemblies, contacts, interrupters, bumpers, dashpots,

bushing current transformers, tank liners, and gaskets.

- Verify that contact sequence is in accordance with manufacturer’s published data. In

the absence of manufacturer’s published data, refer to ANSI/IEEE C37.04.

- Fill tank(s) with filtered oil.

- Inspect bolted electrical connections for high resistance using one or more of the following

methods:

- Use of low-resistance ohmmeter in accordance with Section 7.6.2.B.1.

- Verify tightness of accessible bolted electrical connections by calibrated torquewrench

method in accordance with manufacturer’s published data or Table 100.12.

- Perform thermographic survey in accordance with Section 9.

- Verify cell fit and element alignment, if applicable.

- Verify racking mechanism operation, if applicable.

- Perform contact-timing test.

- Perform mechanism-motion analysis.

- *Perform trip/close coil current signature analysis.

- Verify appropriate lubrication on moving current-carrying parts and on moving and sliding

surfaces.

- Record as-found and as-left operation counter readings.

B. Electrical Tests:

- Perform resistance measurements through bolted connections with a low-resistance

ohmmeter, if applicable, in accordance with Section 7.6.2.A.12.1

- Perform insulation-resistance tests for one minute on each pole, phase-to-phase and phase-toground

with circuit-breaker closed, and across each open pole. Test voltage shall be in

accordance with manufacturer’s published data. In the absence of manufacturer’s published

data, use Table 100.1.

- Perform a static contact/pole resistance test.

- *Perform a dynamic contact/pole resistance test.

- *Perform insulation-resistance tests on all control wiring with respect to ground. Applied

potential shall be 500 volts dc for 300-volt rated cable and 1000 volts dc for 600-volt rated

cable. Test duration shall be one minute. For units with solid-state components, follow

manufacturer’s recommendation.

- Remove a sample of insulating liquid in accordance with ASTM D 923. Sample shall be

tested in accordance with the referenced standard.

- Dielectric breakdown voltage: ASTM D 877

- Color: ANSI/ASTM D 1500

- Power factor: ASTM D 924

- Interfacial tension: ASTM D 971

- Visual condition: ASTM D 1524

- Neutralization number (acidity): ASTM D974

- Water content: ASTM D1533

- Perform minimum pickup voltage tests on trip and close coils in accordance with

manufacturer’s published data.

- Verify correct operation of any auxiliary features such as electrical close and trip operation,

trip-free, antipump function.

- Trip circuit breaker by operation of each protective device. Reset all trip logs and indicators.

- Perform power-factor or dissipation-factor tests on each pole with breaker open and each

phase with breaker closed. Determine tank loss index.

- Perform power-factor or dissipation-factor tests on each bushing equipped with a powerfactor/

capacitance tap. In the absence of a power-factor/ capacitance tap, perform hot-collar

tests. These tests shall be in accordance with the test equipment manufacturer’s published

data.

- *Perform a dielectric withstand voltage test in accordance with manufacturer’s published data.

- Verify operation of heaters.

- Test instrument transformers in accordance with Section 7.10.

C. Test Values – Visual and

Mechanical

- Settings for alarm, pressure, and limit switches shall be in accordance with owner’s

specifications. In the absence of owner’s specifications use manufacturer’s published data.

(7.6.2.A.9)

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value. (7.6.2.A.12.1)

- Bolt-torque levels shall be in accordance with manufacturer’s published data. In the absence

of manufacturer’s published data, use Table 100.12. (7.6.2.A.12.2)

- Results of the thermographic survey shall be in accordance with Section 9. (7.6.2.A.12.3)

- Contact timing values shall be in accordance with manufacturer’s published data.

(7.6.2.A.15).

- Travel and velocity values shall be in accordance with manufacturer’s published data.

(7.6.2.A.16)

- Trip/close coil current values shall be in accordance with manufacturer’s published data.

(7.6.2.A.17).

- Operations counter shall advance one digit per close-open cycle. (7.6.2.A.19)

D. Test Values – Electrical

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value.

- Insulation-resistance values of circuit breakers shall be in accordance with manufacturer’s

published data. In the absence of manufacturer’s published data, use Table 100.1. Values of

insulation resistance less than this table or manufacturer’s recommendations should be

investigated.

- Microhm or dc millivolt drop values shall not exceed the high levels of the normal range as

indicated in the manufacturer’s published data. If manufacturer’s published data is not

available, investigate values that deviate from adjacent poles or similar breakers by more than

50 percent of the lowest value.

- Dynamic contact resistance values shall be in accordance with manufacturer’s published data.

- Insulation-resistance values of control wiring shall not be less than two megohms.

- Insulating liquid test results shall be in accordance with Table 100.4.

- Minimum pickup voltage of the trip and close coils shall conform to the manufacturer’s

published data. In the absence of the manufacturer’s published data, refer to Table 100.20.

- Auxiliary features shall operate in accordance with manufacturer’s published data.

- Protective devices shall operate the breaker per system design.

- Power-factor or dissipation-factor values and tank loss index shall be compared to

manufacturer’s published data. In the absence of manufacturer’s published data, the

comparison shall be made to test data from similar breakers or data from test equipment

manufacturers.

- Power-factor or dissipation-factor and capacitance values shall be within ten percent of

nameplate rating for bushings. Hot collar tests are evaluated on a milliampere/milliwatt loss

basis, and the results should be compared to values of similar bushings.

- If no evidence of distress or insulation failure is observed by the end of the total time of

voltage application during the dielectric withstand test, the test specimen is considered to

have passed the test.

- Heaters shall be operational.

- Results of electrical tests on instrument transformers shall be in accordance with Section

7.10.

NETA ATS

7.6.4 Circuit

Breakers, SF6

A. Visual and Mechanical

Inspection:

- Compare equipment nameplate data with drawings and specifications.

- Inspect physical and mechanical condition.

- Inspect anchorage, alignment, and grounding.

- Verify that all maintenance devices such as special tools and gauges specified by the

manufacturer are available for servicing and operating the breaker.

- Verify the unit is clean.

- When provisions are made for sampling, remove a sample of SF6 gas and test in accordance

with Table 100.13. Do not break seal or distort “sealed-for-life” interrupters.

- Inspect operating mechanism and/or hydraulic or pneumatic system and SF6 gas-insulated

system in accordance with manufacturer’s published data.

- Test for SF6 gas leaks in accordance with manufacturer’s published data.

- Verify correct operation of alarms and pressure-limit switches for pneumatic, hydraulic, and

SF6 gas pressure in accordance with manufacturer’s published data.

- If recommended by manufacturer, slow close/open breaker and check for binding, friction,

contact alignment, and penetration. Verify that contact sequence is in accordance with

manufacturer’s published data. In the absence of manufacturer’s published data, refer to

ANSI/IEEE C37.04.

- Perform all mechanical operation tests on the operating mechanism in accordance with the

manufacturer’s published data.

- Inspect all bolted electrical connections for high resistance using one or more of the

following methods:

- Use of a low-resistance ohmmeter in accordance with Section 7.6.4.B.1.

- Verify tightness of accessible bolted electrical connections by calibrated torquewrench

method in accordance with manufacturer’s published data or Table 100.12.

- Perform a thermographic survey in accordance with Section 9.

- Verify the appropriate lubrication on moving current-carrying parts and on moving and

sliding surfaces.

- Perform contact-timing test.

- *Perform trip/close coil signature analysis.

- Perform mechanism motion analysis.

- Record as-found and as-left operation counter readings.

B. Electrical Tests:

- Perform resistance measurements through all bolted connections with a low-resistance

ohmmeter, if applicable, in accordance with Section 7.6.4.A.12.1.

- Perform insulation-resistance tests in accordance with Table 100.1 from each pole-to-ground

with breaker closed and across open poles at each phase. For single-tank breakers, perform

insulation resistance tests in accordance with Table 100.1 from pole-to-pole.

- Perform a contact/pole-resistance test.

- *Perform insulation-resistance tests on all control wiring with respect to ground. Applied

potential shall be 500 volts dc for 300-volt rated cable and 1000 volts dc for 600-volt rated

cable. Test duration shall be one minute. For units with solid-state components or for control

devices that cannot tolerate the voltage, follow manufacturer’s recommendation.

- Perform minimum pickup voltage tests on trip and close coils in accordance with

manufacturer’s published data.

- Verify correct operation of any auxiliary features such as electrical close and trip operation,

trip-free, and antipump function. Reset all trip logs and indicators.

- Trip circuit breaker by operation of each protective device.

- Perform power-factor or dissipation-factor tests on each pole with the breaker open and on

each phase with the breaker closed.

- Perform power-factor or dissipation-factor tests on each bushing equipped with a powerfactor/

capacitance tap. In the absence of a power-factor/ capacitance tap, perform hot-collar

tests. These tests shall be in accordance with the test equipment manufacturer’s published

data.

- *Perform a dielectric withstand voltage test in accordance with manufacturer’s published data.

- Verify operation of heaters.

- Test instrument transformers in accordance with Section 7.10.

C. Test Values – Visual and

Mechanical

-

- SF6 gas shall have values in accordance with Table 100.13. (7.6.4.A.6)

- Results of the SF6 gas leak test shall confirm that no SF6 gas leak exists. (7.6.4.A.8)

- Settings for alarm, pressure, and limit switches shall be in accordance with manufacturer’s

published data. (7.6.4.A.9)

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value. (7.6.4.A.12.1)

- Bolt-torque levels shall be in accordance with manufacturer’s published data. In the absence

of manufacturer’s published data, use Table 100.12. (7.6.4.A.12.2)

- Results of the thermographic survey shall be in accordance with Section 9. (7.6.4.A.12.3)

- Contact timing values shall be in accordance with manufacturer’s published data.

(7.6.4.A.14)

- Trip/close coil current values shall be in accordance with manufacturer’s published data

(7.6.4.A.15)

- Travel and velocity values shall be in accordance with manufacturer’s published data.

(7.6.4.A.16)

- Operations counter shall advance one digit per close-open cycle. (7.6.4.A.17)

D. Test Values – Electrical

-

- Compare bolted connection resistance values to values of similar connections. Investigate

values which deviate from those of similar bolted connections by more than 50 percent of the

lowest value.

- Insulation-resistance values of circuit breakers shall be in accordance with manufacturer’s

published data. In the absence of manufacturer’s published data, use Table 100.1. Values of

insulation resistance less than this table or manufacturer’s recommendations should be

investigated.

- Microhm or dc millivolt drop values shall not exceed the high levels of the normal range as

indicated in the manufacturer’s published data. In the absence of manufacturer’s published

data, investigate values that deviate from adjacent poles or similar breakers by more than 50

percent of the lowest value.

- Insulation-resistance values of control wiring shall not be less than two megohms.

- Minimum pickup voltage of the trip and close coils shall conform to the manufacturer’s

published data. In the absence of the manufacturer’s published data, refer to Table 100.20.

- Auxiliary features shall operate in accordance with manufacturer’s published data.

- Protective devices shall operate the breaker per the system design.

- Power-factor or dissipation-factor values shall be compared to manufacturer’s published data.

In the absence of manufacturer’s published data, the comparison shall be made to test data

from similar breakers or data from test equipment manufacturers.

- Power-factor or dissipation-factor and capacitance test values shall be within ten percent of

nameplate rating for bushings. Hot collar tests are evaluated on a milliampere/milliwatt loss

basis, and the results shall be compared to values of similar bushings.

- If no evidence of distress or insulation failure is observed by the end of the total time of

voltage application during the dielectric withstand test, the test specimen is considered to

have passed the test.

- Heaters shall be operational.

- Results of electrical tests on instrument transformers shall be in accordance with Section

7.10.

NETA ATS

/ MTS

TABLE

100.1

NETA ATS

/ MTS

TABLE

100.7

NETA ATS

/ MTS

TABLE

100.8

NETA ATS

/ MTS

TABLE

100.12

NETA ATS

/ MTS

TABLE

100.20

|