| Terminology | |

|---|---|

| Electric Arc: |

An electric arc or an arcing fault is the flow of electric current through the air from one conductor to another or to ground. Arcs are generally initiated by a flashover caused by some type of conductor that subsequently vaporizes or falls away, leaving an arc. Arcing faults create many hazards, but the greatest risk is burn injuries due to exposure to the heat generated by the arc. This heat can cause serious, even fatal burns, as well as ignite clothing and other nearby material and objects. In addition, electric arcs can produce molten metal droplets, UV radiation, and explosive air pressure waves. |

| Electric Arc: |

An electric arc or an arcing fault is the flow of electric current through the air from one conductor to another or to ground. Arcs are generally initiated by a flashover caused by some type of conductor that subsequently vaporizes or falls away, leaving an arc. Arcing faults create many hazards, but the greatest risk is burn injuries due to exposure to the heat generated by the arc. This heat can cause serious, even fatal burns, as well as ignite clothing and other nearby material and objects. In addition, electric arcs can produce molten metal droplets, UV radiation, and explosive air pressure waves. |

| Arc Flash Hazard: |

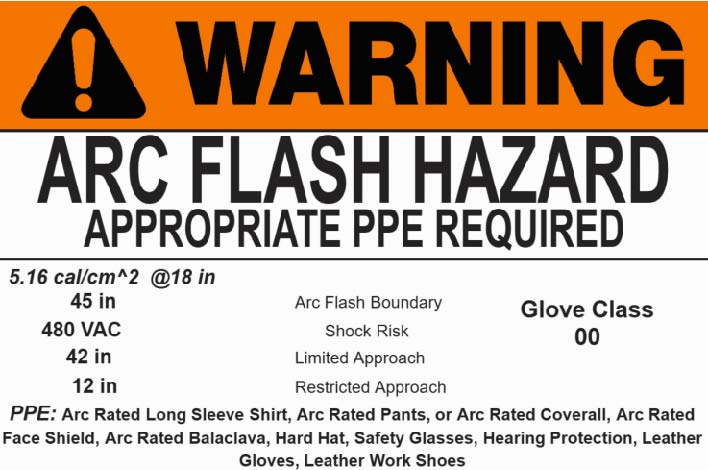

An arc flash hazard is a dangerous condition associated with the possible release of energy caused by an electric arc. An arc flash hazard may exist when energized electrical conductors or circuit parts are exposed or when they are within equipment in a guarded or enclosed condition, provided a person is interacting in a way that can cause an arc (such as switching on or off a breaker or disconnect switch; racking a breaker…things of this nature). Also, under normal operating conditions, enclosed energized electrical equipment that has been properly i nstalled and maintained is not likely to pose an arc flash hazard. |

| Arc Flash Hazard Analysis Report: |

An Arc Flash Assessment / Analysis is a study of the facility’s power system to determine the incident energy available at specific electrical devices that employees would be exposed to while “interacting with” the electrical equipment at the facility. The output of the Assessment/ Analysis is a determination and labeling of the PPE required of the electrical devices, suitability of the devices for service as installed and if there are any miss- coordination issues involved as the system is currently installed. A short circuit current available analysis and the clearing times of the overcurrent devices involved is required to determine the incident energy at the various points in the system. |

| Power Transformer Nameplate Data | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Restricted Approach

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| IEEE 1584-2002 Method | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

There are two distinct mathematical methods of calculating the available arc flash energy present at a specific piece of equipment — both of which are detailed in Annex D of NFPA 70E. IEEE 1584-2002 is titled “IEEE Guide for Performing Arc-Flash Hazard Calculations,” and provides a methodology for calculating prospective arc flash hazards. Based on test data, the IEEE 1584 committee developed empirical equations to calculate arc flash incident energy for AC systems. It is important to understand that the IEEE 1584 equations are valid only for the conditions for which test data was evaluated.These limitations are summarized in the table below summarized in Table 3.1

\(I_{a} = 10^{\color{green} {K}+ 0.662\log_{10}({I_{bf} }) +0.0966\color{red} {V} +0.000526\cdot \color{blue} {G}+ 0.5588\cdot \color{red} {V}\cdot \log_{10}({I_{bf} })-0.00304 \cdot \color{blue} {G} \cdot \log_{10}({I_{bf} }) }\)

\(I_{a} = 10^{0.00402 + 0.983\log_{10}({I_{bf}})}\)

Estimate of Normalized Incident Energy

\(E_{n} = 10^{ \color{green} {K_{1}} + \color{green} {K_{2}} + 1.081\cdot \log_{10}({I_{a} }) + 0.0011\cdot \color{blue} {G}} \)

Estimate of Incident EnergyThe normalized incident energy is used to obtain the estimated incident energy at a normal surface at a given distance and arcing time with equation \(E = 4.184\cdot \color{blue} {C_{f}}\cdot \color{green} {E_{n}}\cdot \left(\begin{array}{c}\frac{t}{0.2} \end{array}\right) \cdot \left(\begin{array}{c} \frac{610}{D} \end{array}\right)^{x} \)

Arc Flash-Protection BoundaryThe distance at which a person without personal protective equipment (PPE) may get a second degree burn that is curable. This is the same as the Arc Flash Boundary discussed in NFPA 70E. \( D_{B} = 610 \cdot \begin{bmatrix} 4.184 \cdot \color{blue} {C_{f}} \cdot \color{green} {E_{n}}\cdot \left(\begin{array}{c}\frac{t}{0.2} \end{array}\right) \left(\begin{array}{c}\frac{1}{E_{b}} \end{array}\right) \end{bmatrix}^{\frac{1}{x}} \)

|

|||||||||||||||||